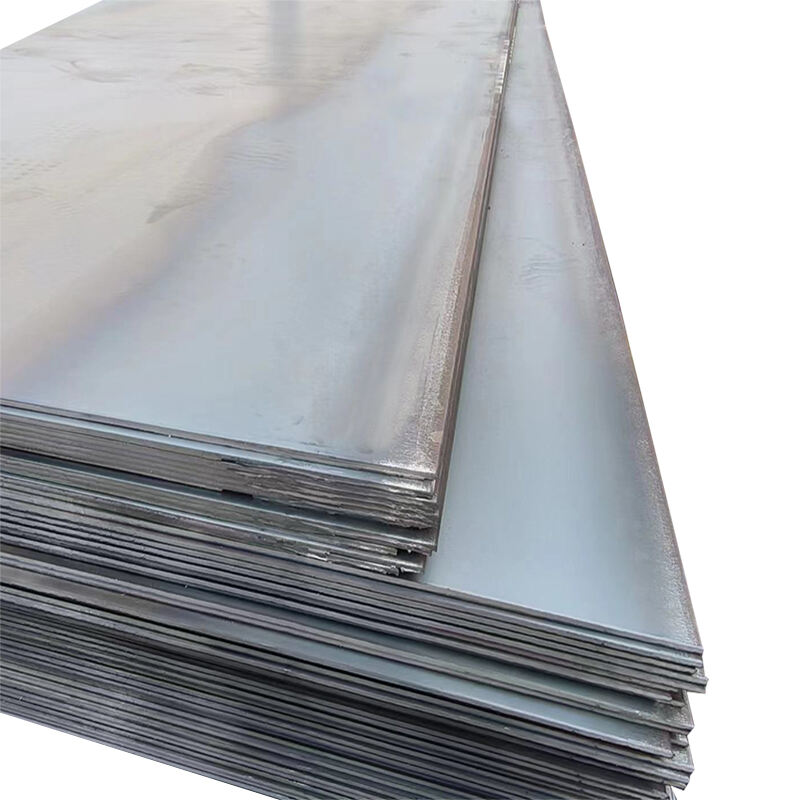

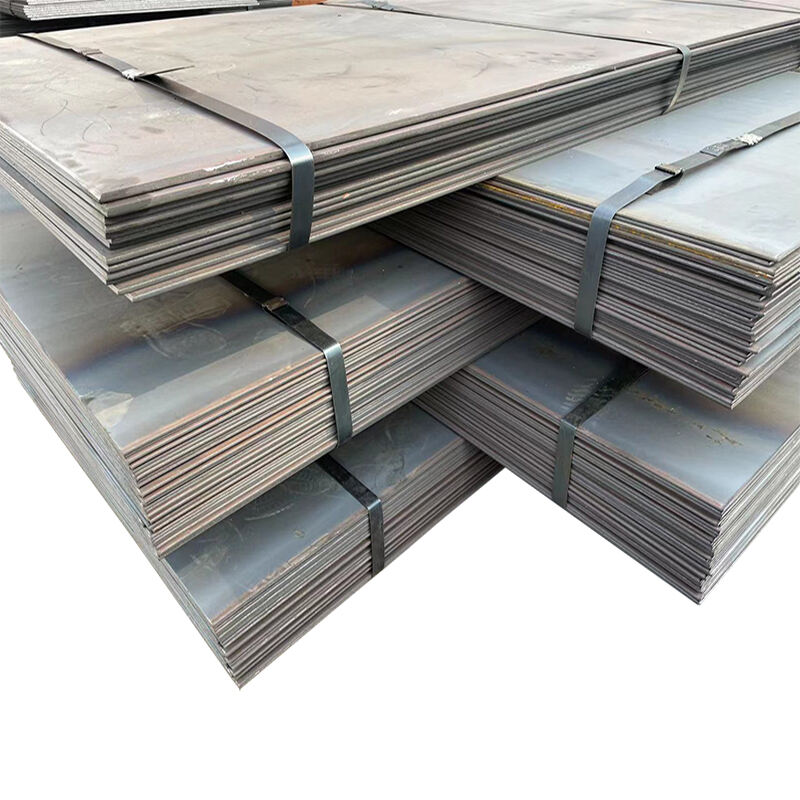

ms plátaþverrýð

MS-blöður, sem eru einnig þekktar sem haldvarpaðar stálblöður, eru grundvallarþáttur í nútíma iðnaði og byggingarverkefnum. Þessar ýmsu notagildar stálplötur eru framleiddar með heitu valningi, sem leidir til sléttu stálplötur með jafna þykkt og yfirburðalega gerð. Plötur hafa oft magn af kolefni á bilinu 0,15% til 0,30%, sem veitir jafnvægi milli styrkleika og vinnanleika. MS-blöður eru fáanlegar í ýmsum stærðum og þykktum, venjulega á bilinu 0,12mm upp í 200mm, sem gerir þær hæfaranlegar fyrir ýmsar notur. Framleiðsluferlið tryggir jafna eiginleika í blöðunum, þar á meðal frábæra sveiflu, myndunarefni og vinnanleika. Þessar plötur fara í gegnum strangar gæðastjórnunaráætlanir, þar á meðal últragljóðsprófanir og mælingar á stærðarnafnum, til að uppfylla alþjóðlegar staðla eins og ASTM og IS tilgreiningar. Yfirborðslykillinn er hægt að sérsníða eftir þörfum, frá venjulegu verksmiðjuútliti til að picklaðar og olíuðar yfirborð, sem bætir öruggleika þeirra í ýmsum umhverfisstöðum. MS-blöður eru lykilþáttur í gerðarverkfræði, vélastöðvarframleiðslu, bílategundum og ýmsum iðnaðarforritum, og borga áreiðanlega afköst og kostnaðsæðar lausnir bæði fyrir smærri og stærri verkefni.