rjúpastaður stálhorn

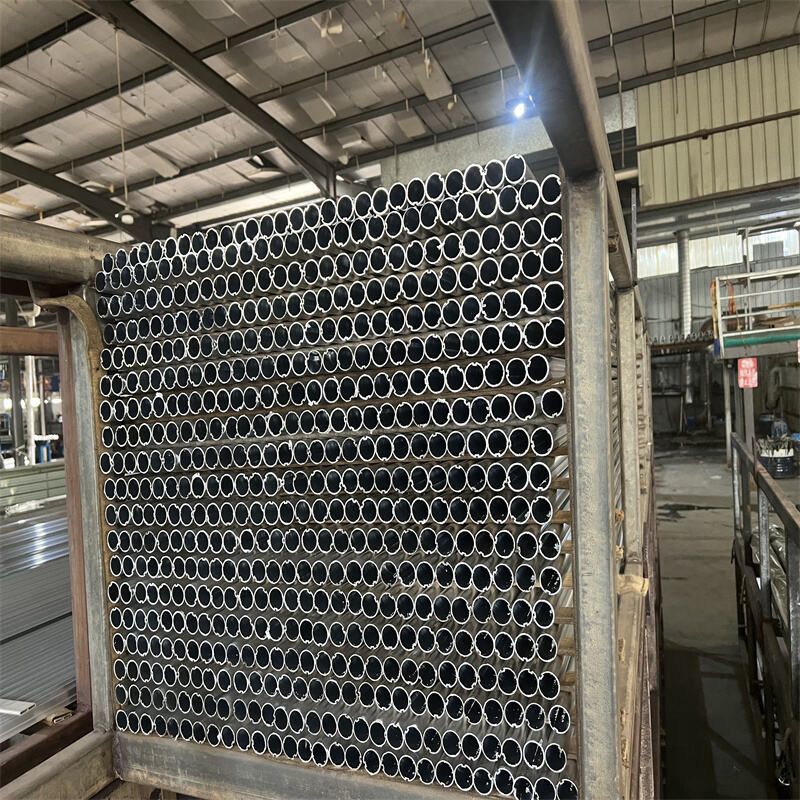

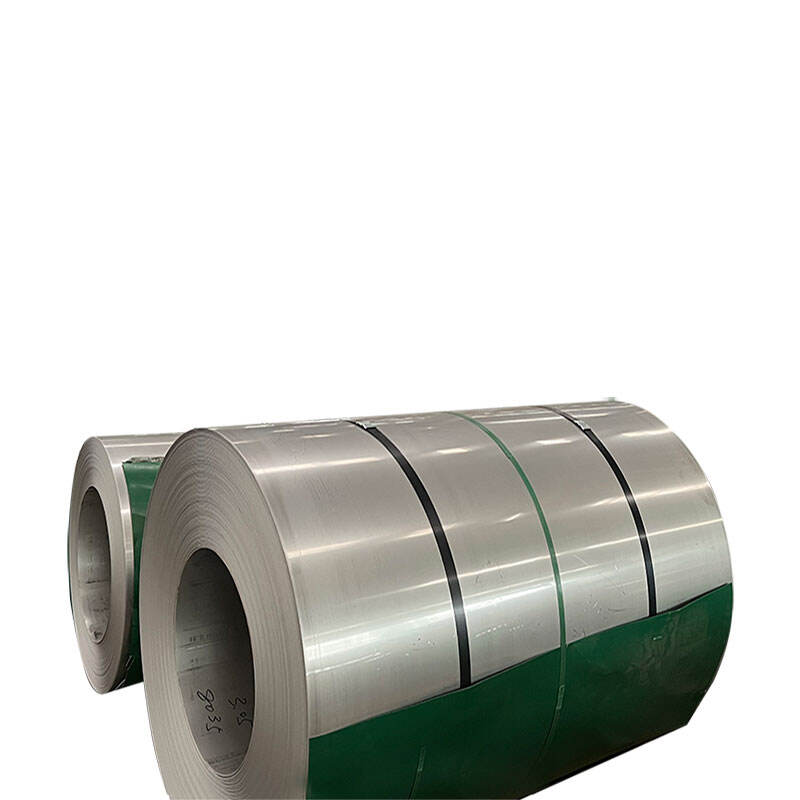

Rafstálshorn er fjölbreytt gerðarhluti sem einkennist af L-shapuðu sniði og er framleiddur úr hákóða legeringu af rafstáli. Þessi grundvallar gerðarhluti sameinar úrslitalega varanleika og ánægjulega viðnámsefni, sem gerir það árangursameyta bæði innandyra og útandyra notkun. Hönnun hornsins inniheldur tvö hornrétt færi jafn eða ójafn löng, sem veita stöðugt stuðning og fyrirheit í ýmsum gerðarforritum. Í sölu eru ýmsar tegundir, meðal annars 304 og 316, sem bjóða mismunandi stig af viðnámsefni og styrkleika sem hentar ýmsum umhverfis ástæðum. Framleiðslu ferlið felur í sér heitt eða kalt valningar aðferðir, sem tryggja nákvæma mælingu og samfellda efnis eiginleika í öllu vöru. Þessi horn leika lykilhlutverk í byggingarverkefnum, iðnaðarstofum og sjávar forritum, veita frábæra getu til að berjast á þyngd á meðan gæði og útlit eru viðhaldið. Eiginleikar efnið til að standa á móti há- og lág hitastigum, efnum og veðuráhrifum gerir það sérstaklega gagnlegt í erfiðum umhverfum þar sem venjuleg stál vörur gætu ekki sinnt verkefnum. Auk þess, veitir slétt yfirborð rafstálshorn einfalda hreinsun og viðhald, sem stuðlar að langtímavara og áreiðanleika í gerðarforritum.