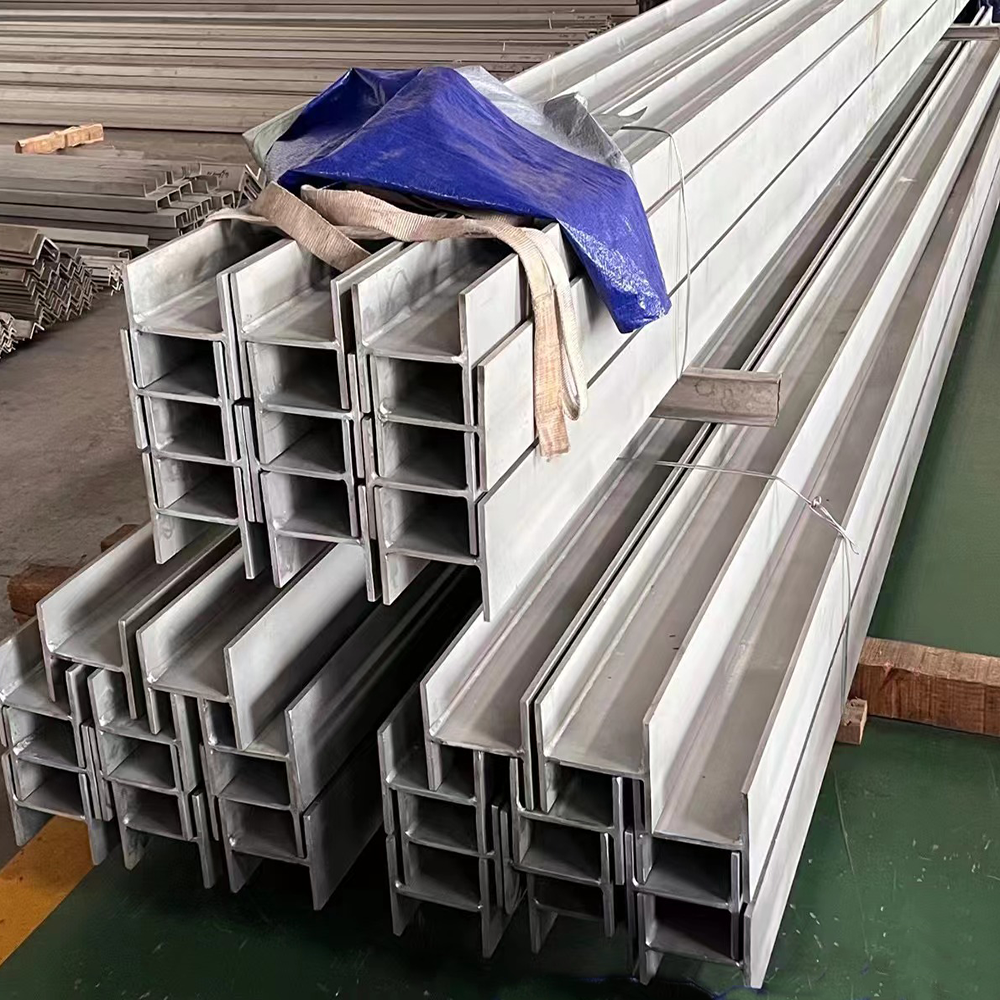

asta in acciaio inossidabile 316 (ss 316 rod)

Barra in acciaio inossidabile 316, conosciuta anche come barra SS 316, rappresenta un prodotto in acciaio inossidabile austenitico di alta qualità che offre un'eccezionale resistenza alla corrosione e ottime proprietà meccaniche. Questo materiale versatile contiene livelli più elevati di nichel e molibdeno rispetto ad altre qualità di acciaio inossidabile, rendendolo particolarmente resistente ai cloruri e ad altri ambienti chimici aggressivi. La forma a barra garantisce un'eccellente lavorabilità ed è possibile tornirla per realizzare svariati componenti destinati a applicazioni impegnative. La sua superiore resistenza alla corrosione pitting e interstiziale la rende ideale per l'uso in ambienti marini, equipaggiamenti per l'elaborazione chimica e produzione farmaceutica. Il materiale mantiene la sua integrità strutturale su un'ampia gamma di temperature, dalle condizioni criogeniche fino a temperature elevate di 870°C. La barra SS 316 mostra una notevole resistenza a trazione, generalmente compresa tra 515 e 690 MPa, combinata a una buona duttilità e un'eccellente saldabilità. Questa combinazione di proprietà ne fa una scelta preferita in applicazioni che richiedono sia resistenza meccanica che resistenza alla corrosione. Il basso contenuto di carbonio del materiale assicura inoltre una migliore resistenza alla sensibilizzazione durante le operazioni di saldatura, riducendo il rischio di corrosione intergranulare.