304 რეზისტენტული მასალის მგზავრო

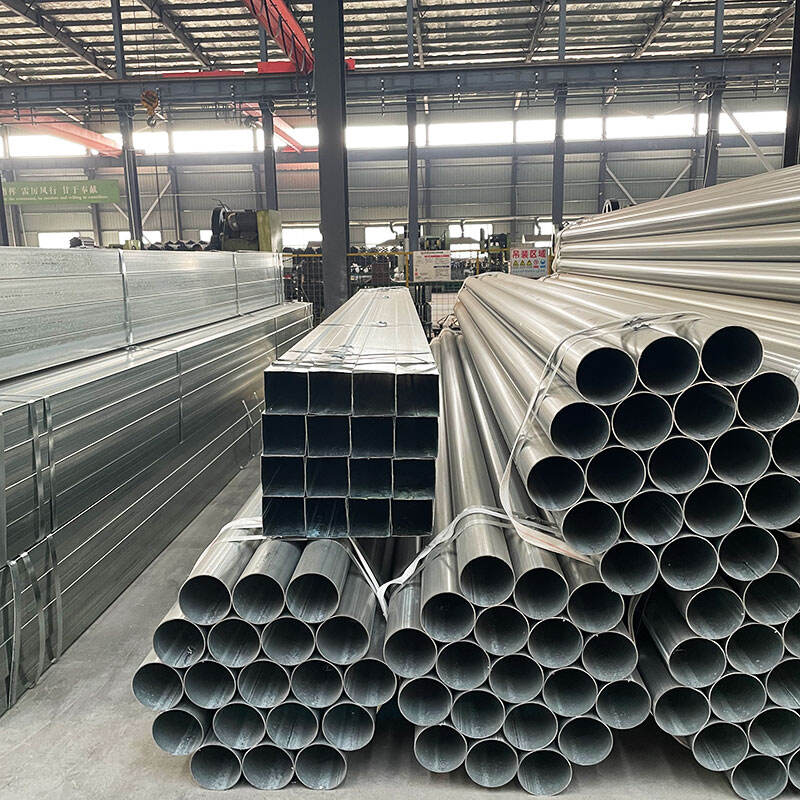

304 უჟანგავი ფოლადის მილები წარმოადგენს ოქროს სტანდარტს სამრეწველო და კომერციული მილების გადაწყვეტებში, რომლებიც აერთიანებენ განსაკუთრებულ გამძლეობას და კოროზიის გამძლეობას. ეს აუსტენიტული ფოლადის შემადგენლობა, რომელიც დაახლოებით 18% ქრომისა და 8% ნიკელის შემადგენლობაშია, ქმნის თვითშემკეთებელ პასიურ ფენას, რომელიც უზრუნველყოფს გამორჩეულ დაცვას სხვადასხვა გარემოს პირობებისგან. მილსადენი ინარჩუნებს სტრუქტურულ მთლიანობას ფართო ტემპერატურის დიაპაზონში, უკიდურესი სიცივიდან მაღალი სიცხემდე, რაც იდეალურია სხვადასხვა გამოყენებისთვის. წარმოების პროცესში, ეს მილები ექვემდებარებიან ხარისხის კონტროლის მკაცრ ზომებს, რაც უზრუნველყოფს კედლის მუდმივ სისქეს, ზუსტ ზომებს და გლუვ ზედაპირს. ხელმისაწვდომია სხვადასხვა ზომისა და გრაფიკის, 304 უჟანგავი ფოლადის მილები ფართოდ გამოიყენება საკვები პროდუქტების გადამამუშავებელი დაწესებულებები, ქიმიური ქარხნები, ფარმაცევტული წარმოება და არქიტექტურული გამოყენებები. მათი შესანიშნავი შედუღებადი და ფორმირებადი შესაძლებლობა საშუალებას იძლევა მრავალმხრივი მონტაჟის ვარიანტები, ხოლო მათი არამაგნიტური თვისებები მათ გამოდგება სპეციალური ელექტრონული და სამედიცინო გარემოში. მასალის თანდაყოლილი წინააღმდეგობა სკალერირებასა და ოქსიდაციას, მისი განსაკუთრებული მექანიკური თვისებების კომბინაციაში, უზრუნველყოფს ხანგრძლივ მოხმარების სიცოცხლეს მინიმალური მოვლა-პატრონობის მოთხოვნით. ეს მილები ასევე აკმაყოფილებენ საერთაშორისო სტანდარტებსა და სპეციფიკაციებს, მათ შორის ASTM A312 და ASME SA312, რაც უზრუნველყოფს საიმედო შესრულებას სხვადასხვა სამრეწველო პროგრამებში.