زۆری گشتی بەرگرین بۆ ئەوەی دەستکاری بکات

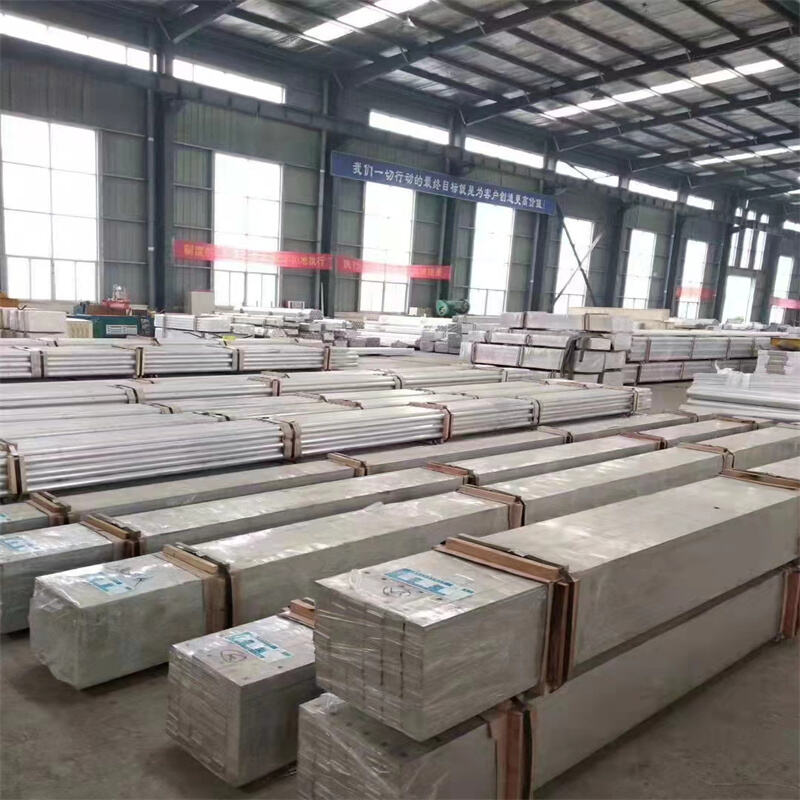

Berxwedana aborî ya ji 201 sêrîl û çêlava ku bi dest pê de dimîne, di pêşî de bihayê wê ye, lê di rêya pêşdankirinê de nirxa wê mezin dibe. Teşkîla wê ya guherbar, bi kêmkirina nîkelê wê re, bihayê wê bi qasî gelek kêm dike û di heman demê de performansa wê jî biparêze. Formkirina baş û civîna wê ya baş, bi kêmkerena hewcedariya ji bo amûrên taybet û teknîkên taybet, bihayê pêşandanê kêm dike. Hejmartina wê di formata çêlavan de, bi rê ve birina û tomarekirina materyalê kêm û bihayê operasyonê jî kêm dike. Kalîteya domdar û performansa wê ya pêwîst, bi kêmkirina kêmkirina materyal û karên nûjen, bihayê wê ya aborî zêde dike. Hemî van faktoran bi hev re dikarin 201 çêlava sêrîl wekî bijareke aborî barê pîşesazên ku dixwazin bihayê produksiyonê kêm bikin û di heman demê de kalîteyê jî biparêzin.