penyedia gulungan keluli tahan karat

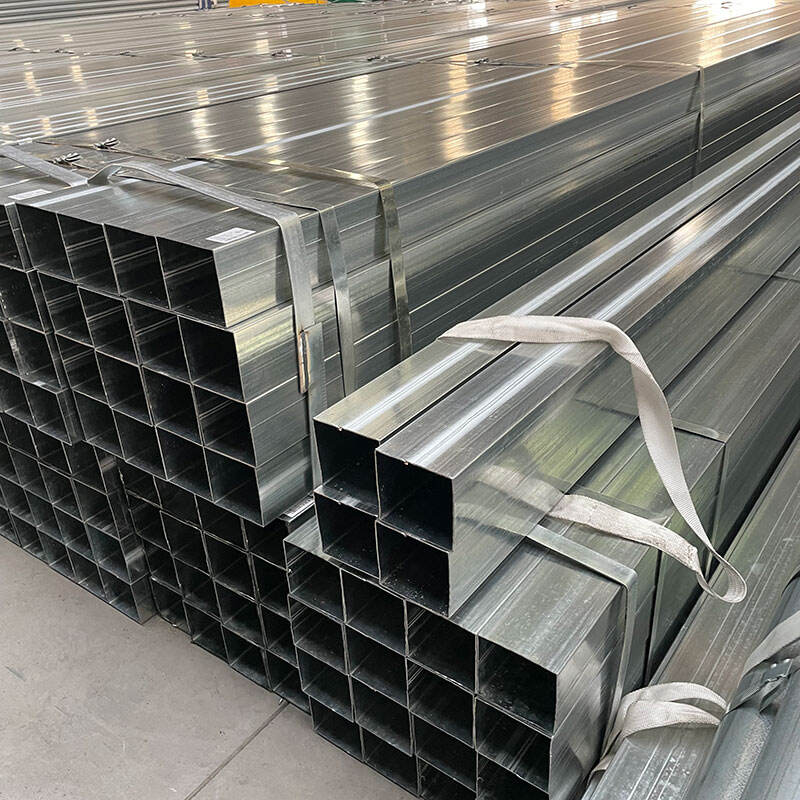

Seorang pembekal gegelung keluli tahan karat bertindak sebagai penghubung utama dalam rantai pembuatan dan pengedaran logam, menyediakan bahan keluli tahan karat berkualiti tinggi dalam bentuk gegelung kepada pelbagai industri. Pembekal-pembekal ini mengekalkan inventori yang luas bagi pelbagai gred, ketebalan, dan lebar gegelung keluli tahan karat, memastikan ketersediaan serta-merta untuk memenuhi keperluan pembuatan yang pelbagai. Pembekal moden menggunakan peralatan pemprosesan terkini, termasuk talian penghancuran presisi, kemudahan potong mengikut panjang, dan sistem kawalan kualiti canggih untuk menghantar produk yang memenuhi spesifikasi yang tepat. Mereka menawarkan pelbagai jenis kemasan permukaan dari kemasan kilang sehingga permukaan yang digilap tinggi, memenuhi keperluan estetika dan fungsian. Peranan pembekal meluas melampaui pengedaran semata-mata, merangkumi perundingan teknikal, panduan pemilihan bahan, dan perkhidmatan pemprosesan khusus. Kemudahan mereka dilengkapi dengan peralatan pengendalian terkini dan kawasan penyimpanan terkawal iklim untuk mengelakkan kehausan bahan. Ramai pembekal juga menyediakan perkhidmatan bernilai tambah seperti pengsyuaran tepi, aplikasi perlindungan permukaan, dan penyelesaian pembungkusan khusus. Mereka memberi perkhidmatan kepada pelbagai industri dari automotif dan angkasa lepas hingga pembinaan dan pengeluaran peralatan, mematuhi piawaian kualiti antarabangsa dan pensijilan bahan dengan ketat.