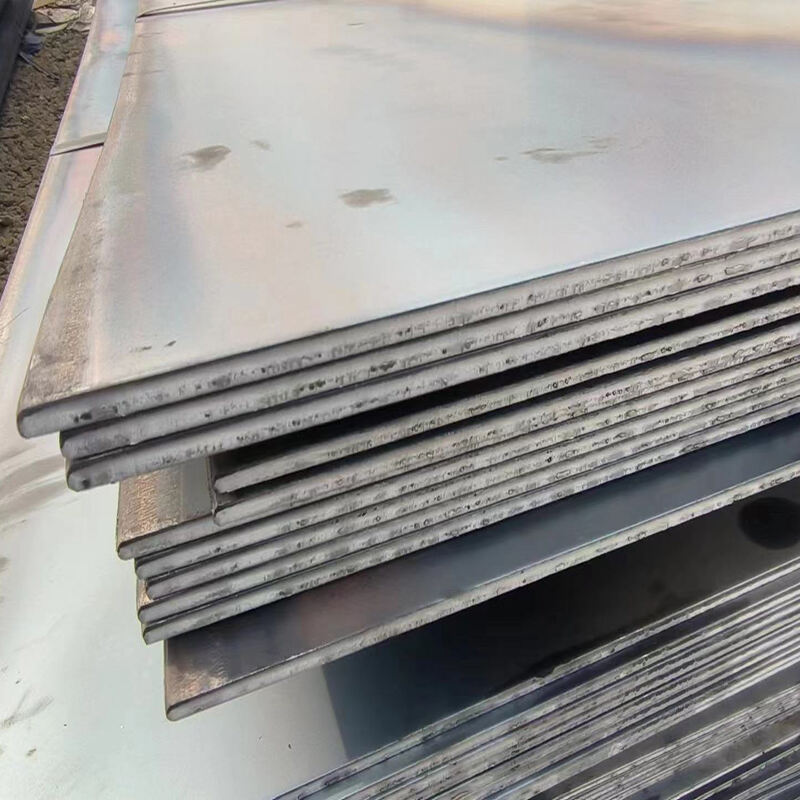

310s stainless steel sheet

३१०एस स्टेनलेस स्टील शीट एउटा उच्च-प्रदर्शन अस्टेनिटिक ग्रेड सामग्री हो जुन आफ्नो अतुलनीय ताप र जंग प्रतिरोधक क्षमताका लागि प्रसिद्ध छ। यो प्रीमियम ग्रेड स्टेनलेस स्टीलमा लगभग २५% क्रोमियम र २०% निकल हुन्छ, जुन ११५०°सी तापक्रम सम्मका उच्च-तापमान अनुप्रयोगहरूका लागि विशेष रूपमा उपयुक्त बनाउँछ। शीटको विशिष्ट रासायनिक संरचनाले चरम वातावरणमा अक्सिडेशन, कार्बुराइजेशन र सल्फाइडेशनको विरुद्ध उत्कृष्ट प्रतिरोध प्रदान गर्दछ। यी विशेषताहरूले यसलाई विभिन्न औद्योगिक अनुप्रयोगहरूका लागि आदर्श विकल्प बनाउँछ, विशेष गरी ती क्षेत्रहरूमा जहाँ सामग्रीले आक्रामक रासायनिक वातावरण र उच्च तापमानलाई सहन गर्नुपर्दछ। ३१०एस ग्रेडले कोठाको तापमान र उच्च तापमान दुवैमा उत्कृष्ट यांत्रिक गुणहरू प्रदर्शन गर्दछ, गम्भीर सञ्चालन अवस्थाहरूमा पनि यसको संरचनात्मक एकाग्रता र स्केलिङको प्रतिरोध बनाए राख्दछ। सामग्रीको बहुमुखी प्रतिभालाई यसको राम्रो फर्मेबिलिटी र वेल्डेबिलिटीले बढायो, विशिष्ट अनुप्रयोग आवश्यकताहरूलाई पूरा गर्न विभिन्न निर्माण विधिहरूको अनुमति दिन्छ। यसको माइनस चुम्बकीय गुणहरू र उच्च तापमानमा लामो समयसम्म जारी रहेपछि पनि यसको अस्टेनिटिक संरचनालाई बनाए राख्ने क्षमताले यसलाई विशेष औद्योगिक अनुप्रयोगहरूमा विशेष मूल्यवान बनाउँछ। सतहको फिनिसलाई विभिन्न विनिर्देशहरू पूरा गर्न कस्टमाइज गर्न सकिन्छ, मानक मिल फिनिस देखि उच्च रूपमा पोलिस गरिएको सतहहरू सम्म, दुवै कार्यात्मक र सौन्दर्य आवश्यकताहरूमा लचिलोपन प्रदान गर्दछ।