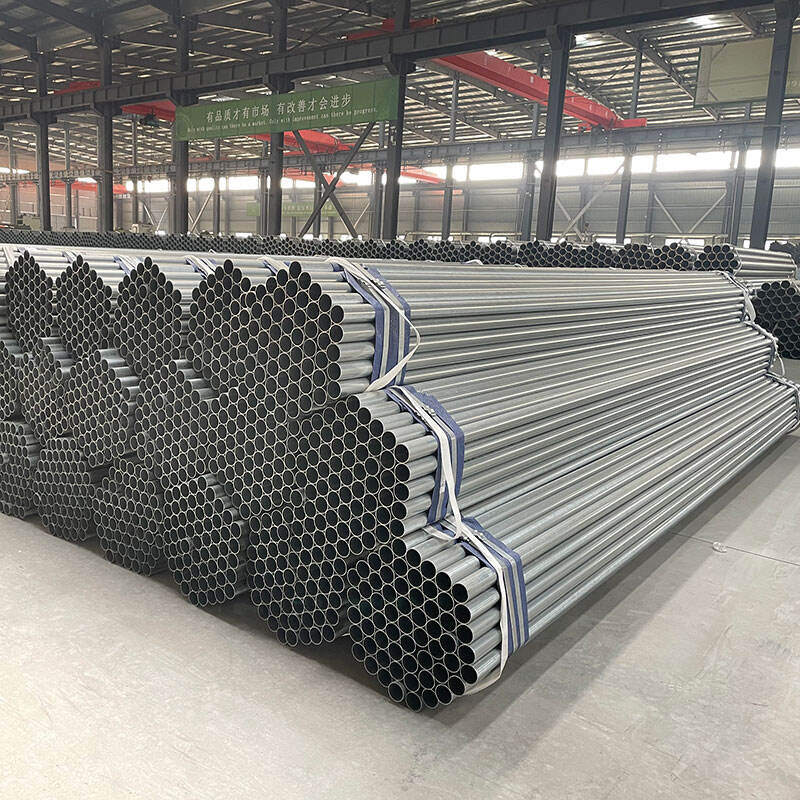

c beam steel

C beam steel, na kilala rin bilang channel steel o C-channel, ay kumakatawan sa isang pangunahing elemento sa modernong konstruksyon at inhenyeriya. Ang adaptableng steel profile na ito ay may natatanging C-shaped cross-section, na binubuo ng isang web at dalawang parallel flanges, na nagpapahusay sa iba't ibang aplikasyon na nangangailangan ng pagtitiis ng bigat. Ang natatanging disenyo nito ay nag-aalok ng mahusay na strength-to-weight ratios, na nagbibigay ng matibay na suporta habang pinapanatili ang structural efficiency. Ginawa sa pamamagitan ng hot-rolling processes, ang C beam steel ay mayroong mataas na mechanical properties, kabilang ang mataas na tensile strength, kamangha-manghang tibay, at hindi mapapanis na paglaban sa bending at torsional forces. Ang mga structural member na ito ay may iba't ibang sukat at espesipikasyon, karaniwang nasa saklaw mula 3 hanggang 15 pulgada ang lalim, na nagpapahintulot sa mga inhinyero at kontratista na pumili ng pinakanggigingkop na dimensiyon para sa partikular na proyekto. Ang versatibilidad ng materyales ay sumasaklaw sa maraming aplikasyon, kabilang ang mga building frameworks, support beams, machine frames, at pagmamanupaktura ng industrial equipment. Ang pinangangasiwaang paggawa ng C beam steel ay nagpapanatili ng pare-parehong kalidad at maaasahang pagganap sa iba't ibang aplikasyon, samantalang ang paglaban nito sa korosyon, lalo na kapag maayos na ginamot o galvanized, ay nag-aambag sa mas matagal na serbisyo at nabawasan ang pangangailangan sa pagpapanatili.