Yuqori mexanik xususiyatlar va chidamlilik

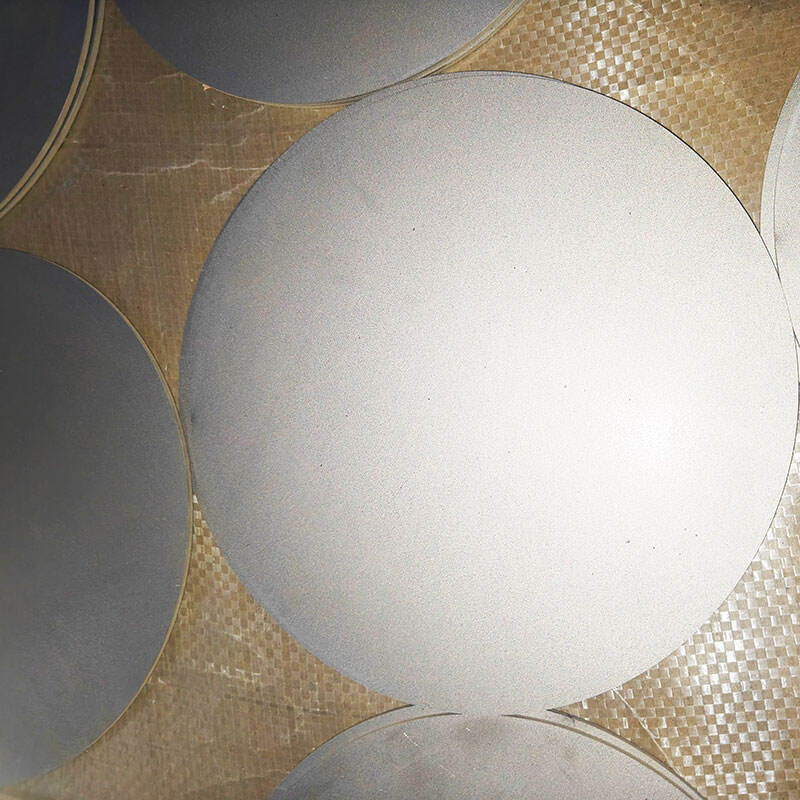

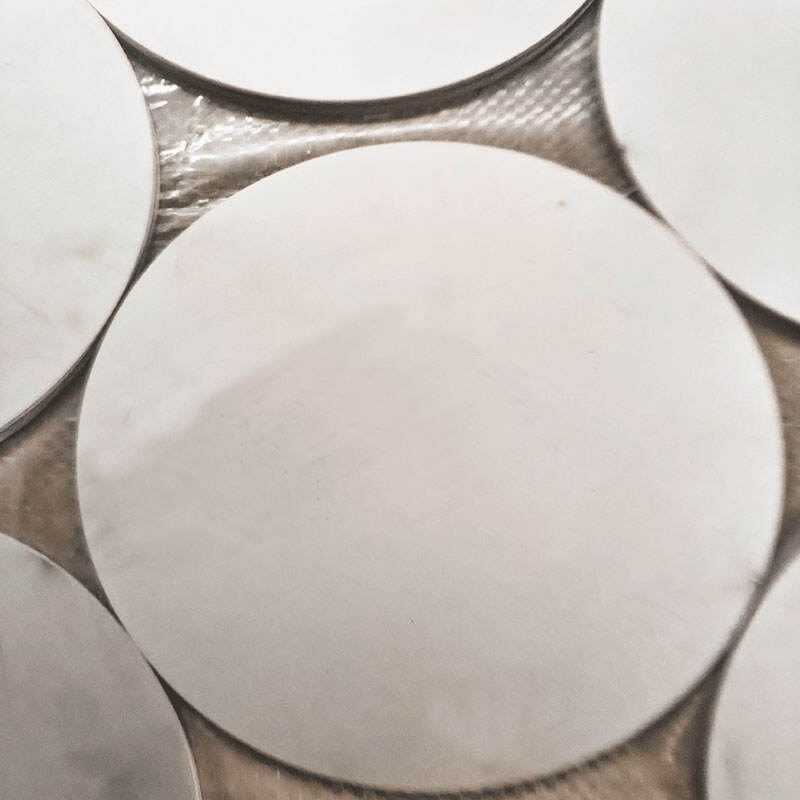

Titan qotishma varaqalari materialshunoslik muhandislik sohasida ularni boshqa materiallardan ajratib turadigan ajoyib mexanik xususiyatlarga ega. Bu qotishmalarining noyob kristall strukturasi yuqori cho'zilish chidamliligi va past zichlikning ajoyib kombinatsiyasini ta'minlab, ko'p muhandislik materiallaridan oshib ketadigan og'irlikka nisbatan mustahkamlik nisbatini yaratadi. Bu xususiyat konstruktsiya muhandislari yengilroq, lekin mustahkamroq strukturalarni yaratish imkonini beradi, ayniqsa aviatsiya va avtomobil sohalarida foydalidir. Materialning yuqori oqish chidamliligi, odatda 830 dan 924 MPagacha bo'lgan oraliqda, yuk ostida doimiy deformatsiyalangan holda qolishga qarshilik ko'rsatadi. Shuningdek, bu varaqalar ajoyib chayqilishga chidamliligi namoyon qiladi va millionlab kuchlanish tsikllaridan keyin ham o'z strukturaviy butunligini saqlab turadi. Materialning elastik moduli taxminan 114 GPa bo'lib, qattiqlik va moslashuvchanlik o'rtasidagi muvozanjli holatni ta'minlab, optimallik yukni taqsimlash va tebranishlarni so'rish uchun imkon beradi. Bu xususiyatlar kriogenik sharoitdan boshlab yuqori haroratlarga qadar keng temperaturaviy diapazonda barqaror bo'lib, varaqalarni turli sohalarda qo'llash uchun ko'p tomonlama material qiladi.