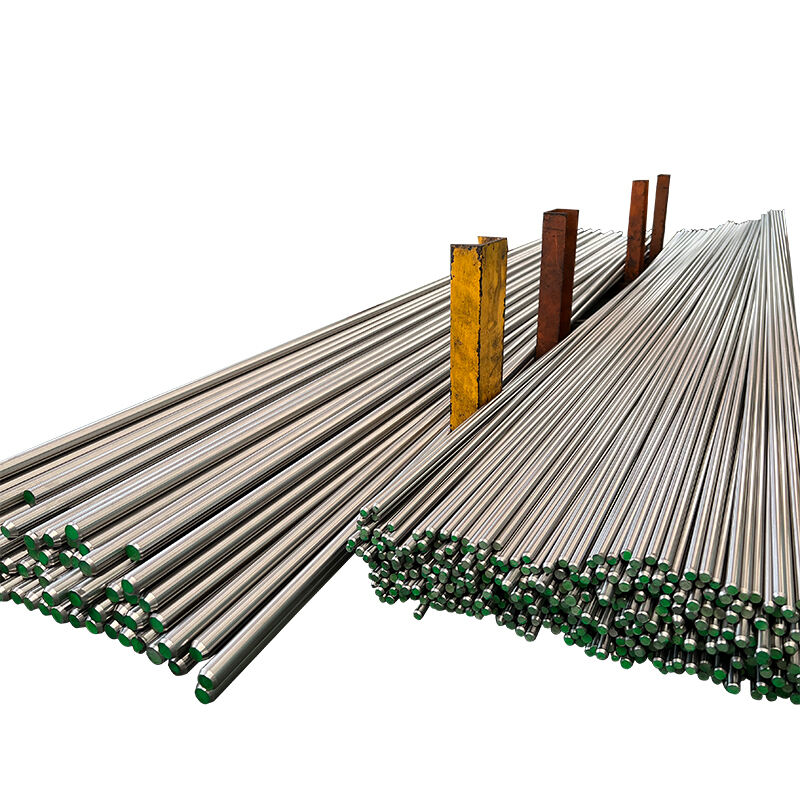

In the dynamic world of engineering and manufacturing, stainless steel rods stand as pillars of innovation and reliability. These cylindrical metal components have revolutionized countless industrial applications, offering unparalleled strength, durability, and corrosion resistance. From aerospace engineering to medical devices, stainless steel rods have become indispensable elements that shape our modern technological landscape.

The significance of stainless steel rods extends far beyond their basic structural properties. Their unique combination of mechanical characteristics and chemical resistance makes them the preferred choice for engineers and designers across various sectors. As we delve deeper into their applications, we'll discover how these versatile components continue to drive innovation and reliability in engineering projects worldwide.

In heavy industrial settings, stainless steel rods play a crucial role in equipment manufacturing and machinery components. They serve as essential elements in hydraulic systems, where their corrosion resistance and strength ensure reliable performance under high pressure and challenging conditions. Manufacturing plants rely on stainless steel rods for conveyor systems, robotic arms, and automated assembly lines, where precision and durability are paramount.

The automotive industry particularly benefits from stainless steel rods in various applications, from engine components to suspension systems. These components withstand extreme temperatures, mechanical stress, and chemical exposure while maintaining their structural integrity. The consistency and reliability of stainless steel rods make them invaluable in maintaining production quality and operational efficiency.

In the construction sector, stainless steel rods form the backbone of many structural reinforcement applications. They're extensively used in concrete reinforcement, particularly in environments where traditional carbon steel might be vulnerable to corrosion. Bridges, marine structures, and high-rise buildings benefit from the superior strength-to-weight ratio and longevity of stainless steel rods.

Infrastructure projects increasingly rely on stainless steel rods for their durability and minimal maintenance requirements. From handrails and security barriers to architectural features, these versatile components contribute to both the structural integrity and aesthetic appeal of modern construction projects.

The aerospace industry demands materials that combine lightweight properties with exceptional strength, making stainless steel rods an ideal choice. They're used in landing gear assemblies, control systems, and structural supports throughout aircraft design. The high tensile strength and resistance to temperature variations make these components crucial for aviation safety and reliability.

Engineers in aerospace manufacturing particularly value the consistency and precision possible with stainless steel rods. Whether in commercial aircraft or space exploration vehicles, these components must meet stringent quality standards and perform reliably under extreme conditions.

In railway engineering, stainless steel rods find applications in both rolling stock and infrastructure. They're essential components in brake systems, suspension mechanisms, and coupling devices. The ability to withstand constant vibration and environmental exposure makes them ideal for these demanding applications.

Marine engineering relies heavily on stainless steel rods for their exceptional corrosion resistance in saltwater environments. From ship propulsion systems to deck equipment, these components provide the durability needed for maritime applications while requiring minimal maintenance.

The medical industry depends on stainless steel rods for manufacturing precise surgical instruments and equipment. Their biocompatibility and ability to maintain sterility make them essential in developing everything from surgical tools to implants. The material's resistance to repeated sterilization processes ensures long-term reliability in medical applications.

Modern surgical robots and precision equipment incorporate stainless steel rods in their mechanical systems, providing the accuracy and dependability required for critical medical procedures. The material's smooth surface finish and resistance to bacterial growth make it ideal for medical engineering applications.

In pharmaceutical manufacturing, stainless steel rods are crucial components in processing equipment and laboratory apparatus. They maintain chemical purity and prevent contamination during drug production processes. The material's resistance to various chemicals and cleaning agents ensures consistent quality in pharmaceutical manufacturing.

Clean room equipment and sterile processing systems rely on stainless steel rods for their structural components and mechanical systems. Their smooth surface finish and ease of cleaning make them ideal for maintaining the strict hygiene standards required in pharmaceutical production.

The growing renewable energy sector extensively uses stainless steel rods in solar panel mounting systems and wind turbine components. Their weather resistance and durability make them ideal for long-term outdoor installations. These components play a crucial role in ensuring the reliability and efficiency of renewable energy infrastructure.

In solar thermal systems, stainless steel rods are used in heat exchangers and support structures, contributing to the overall efficiency and longevity of the installations. Their ability to withstand temperature extremes and environmental exposure makes them essential in sustainable energy solutions.

Nuclear power facilities rely on stainless steel rods for various critical applications, from fuel rod supports to cooling system components. The material's resistance to radiation and high temperatures makes it indispensable in nuclear engineering. The precision and quality control possible with stainless steel rods ensure safety and reliability in nuclear power generation.

Control rod systems and structural supports in nuclear reactors benefit from the dimensional stability and corrosion resistance of stainless steel rods. Their performance under extreme conditions contributes to the safe and efficient operation of nuclear power plants.

Stainless steel rods achieve their corrosion resistance through their chromium content, which forms a protective oxide layer on the surface. This passive layer automatically reforms when damaged, providing continuous protection against corrosion and chemical attack. The addition of other elements like nickel and molybdenum further enhances this corrosion resistance for specific applications.

Manufacturers employ rigorous quality control measures, including material composition testing, dimensional accuracy checks, and surface finish inspections. Advanced testing methods such as ultrasonic testing and magnetic particle inspection ensure the absence of internal defects. Each batch undergoes mechanical property testing to verify strength, hardness, and other critical characteristics.

Yes, stainless steel rods can be customized through various manufacturing processes to meet specific requirements. This includes different diameter sizes, lengths, surface finishes, and heat treatments. Manufacturers can also modify the chemical composition within allowable ranges to optimize properties for particular applications, ensuring optimal performance in diverse engineering contexts.

Hot News

Hot News2025-01-03

2024-10-23

2024-11-15