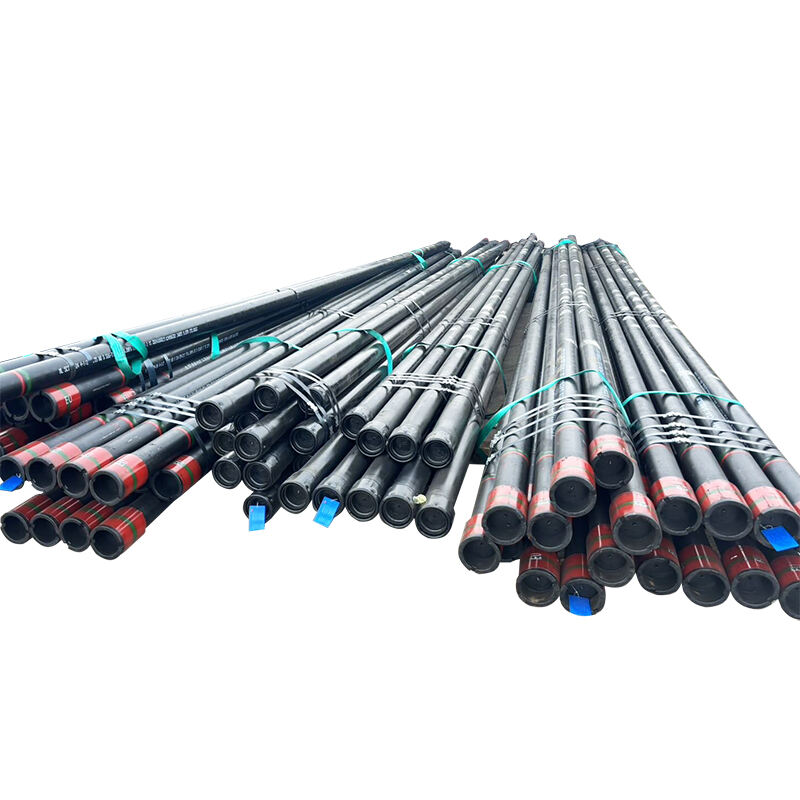

carbon steel pipe

Imiphi yamadoda we-carbon yi-component esikhundleni esikhulu kwinkqubo yobuso bendustriya, enobuchwepheshe bokwenza nezisebenziso ezingaphezulu. Le mpipe yenziwa ngokuchanekileyo ngokuxhuma i-iron ne-carbon, okungenani kungaba phakathi kwe-0.05% kunye ne-2.1% yecarbon, oku kungenxa ye-strong ne durability. Le mpipe zine composition efanayo kwaye yonke into engaphandle kwe-structure, ekunene kwaye kusebenza ngokulandelelana nazo zonke iindlela zokusebenza. Zinceda kakhulu kwiindawo ezinekulu kakhulu, kwaye zinokusebenziswa kwiindawo zokuthunyelwa kwezinto ezingenakuphela, amasithandi olwandle, kunye nezisebenziso zemecanical. Imiphi yamadoda we-carbon ziyafumaneka ngokuchanekileyo, nezihamba ezahlukileyo, zokwamkela amapressure ezingaphezulu kunye nezinyathelo zokufaka. Indlela yazo ukwenza ingxake ngokuphambene noma ngokudlala ngokushushu, emva koko kubekwa kwiindlela zokunceda i-mechanical properties. Le mpipe zenza i-resistance ekhoyo kwezisebenziso zemecanical, zokwamkela ukufakwa ngaphantsi kwenhlanu kunye ngapakade. Iindlela zazo zokwenza zinceda ukwengeka kwezindlela zokudlala kunye nezisebenziso zokulungisa, zokwenza ukufaka kunye nokulungisa kube lula. Kwizindawo zindustriya, imiphi yamadoda we-carbon ziyasebenziswe kakhulu kwiintlawulo zokuthunyelwa kwezinto ezingenakuphela, kwiintlawulo zokunquma amadoda, kunye nezindawo zokwenza i-chemical, apho ubunzima bazo nezisebenziso zazo zikhoyo.