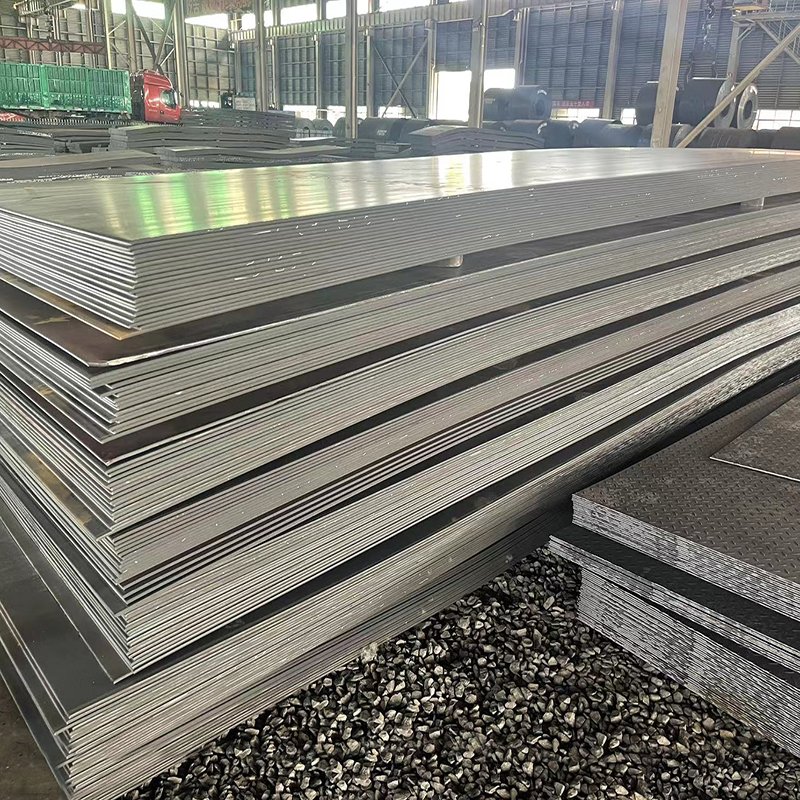

carbon steel sheet

I-steel esikhundleni yekhabhoni yinto egcinwe kakhulu neyisetyenziswa ngokukhawuleza engxenye yemali ephakeme, ukhuthaze nezinhloso zokusebenza. Iyakhelwe ngokucacileyo ngokudibanisa i-iron ngekhabhoni, le ngxenye zinemali khabhoni ekhulu kwe-0.05% ukuya kuma-2.1%. Ukulawulwa okucacileyo komlinganiso wemali khabhoni kuvumela abasebenzisi ukuyakha amaqatha afaka izici zokusebenza ezahlukahlukene ngokwesicelo. Le ngxenye iqukwe kakhulu ngemigomo yokuhlinzeka, ngokudla ngokugcinwa kwezulu, ukugcinwa kwegazi, nokulungisa ngokwendalo, ukuba fikelela kutholwa kwezilinganiso neziciko zokuphawuka. I-steel esikhundleni yekhabhoni inemali yokugqibela, ukulungiswa nezici zokulungisa, kuyilona enokwenzeka ngokukhawuleza kuzo zonke izinhloso zokusebenza. Iyagqibiwa kakhulu kuzo zonke izinhloso zokusebenza ngokwesicelo ngokuthi inemali yokuthula kanye nokuthula kwegazi, ekuvumelana ngokusebenza kakhulu ngokwemigomo yemisebenzi. Izici zomlinganiso zokusebenza zenza kuba yimfuneko yokuthula kwegazi, ukuguqula kwezulu, nezici zokulawulwa kwegazi, ukuze kutholwe ukusebenza ngemva kwezinsuku. Kuzo zonke izindlela zokuyakha ngokuqala, i-steel esikhundleni yekhabhoni iyisikali esibalulekileyo kuzo zonke izinhloso zokusebenza, kuzo zonke izindlela zokuyakha, kuzo zonke izinhloso zokusebenza kwezimali, nezinhloso zokusebenza kwezimali. Ukusebenzisa kakhulu kuvumela ukusebenzisa izindlela ezahlukahlukene zokugqibela, ngokudla ngokubhala, ukuphawula, noma ukulayela, ukuthuthukisa ukusebenza kwayo ngokulawulwa kwegazi neziciko zokujonga.