isibhetho sikhopho somphalisi

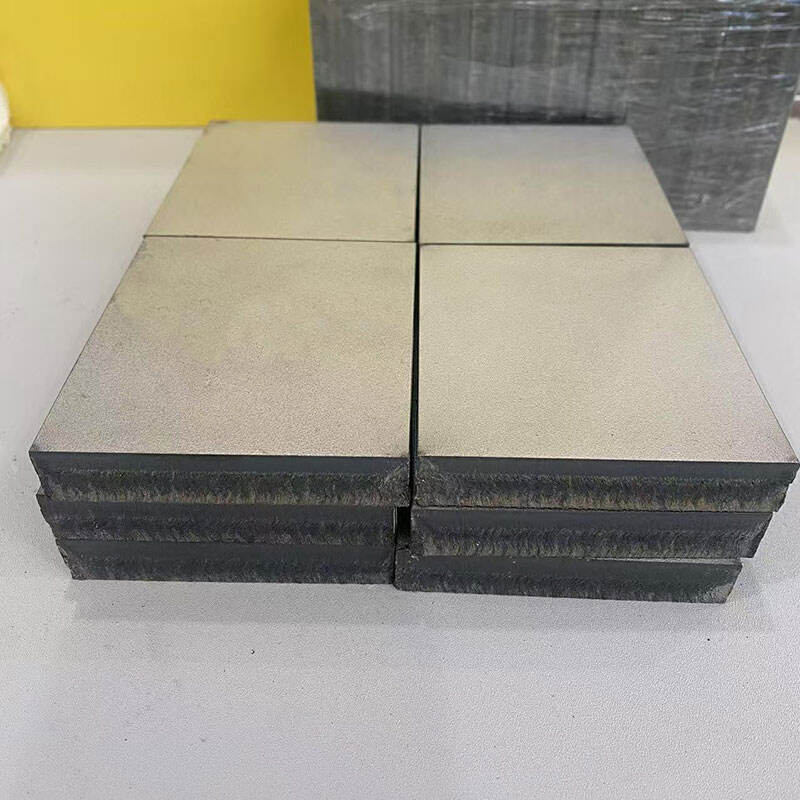

Imithambo yesiliva iyabonisa into ebalulekile kanye nezilandelayo zokusebenza kwemifanekiso, ibhondelela okusebenzisa kahle ukulayela nokuxhumana kweziliva nangokuphelele kweziliva kanye nokuthwasa. Le mithambo ikhiwile ngokusebenzisa imicambo yokurola engqinelwe, kubangela ukulingana kwethickness kanye nokubaluleka kwezifiso. Le nto iyabonisa ukungcola kakhulu kweziliva kanye nokulwa, kuyindlela yokuba yisikali kuzindlela zangaphakathi nezangaphandle. Imithambo yesiliva ikhona kwezindleke ezahlukene, ekuhlukene nezibhontsha ezingaphansi kweziliva kuye kweziliva ezinkulu zokusebenza kwemifanekiso, kubangela ukutholakala kwezidingo zezinhloso ezahlukene. Imicimbi yazo ebalulekile yokulima amandla kuyindlela yokuba yisikali kuzindlela zokupheya kanye nezokubhantsha izinto. Umbala wazo ojwayelekile ophuzi kanye nobomvu ubhona ukuthuthwa okuhle ngemuva kwesikhathi, kubangela ukuthwasa kwayo kanye nokuphela kwezifazwe. Imicambo yokuqina kweminyaka lelizwe iyagcina ukubaluleka okulinganayo emithambeni, nangokukhetha izindleke ezahlukene zokuthwasa kanye nezifiso ukwenzela ukuthi kutholakale ukulokelwa kwezinhloso eziyisikali. Le mithambo ingakwe ngokulula ngokugcina, ukubhendula kanye nokuthwasa, kuyindlela yokuba yisikali kuzindlela zokubhantu kanye nezokwenza ngokulandelako, kubangela ukutholakala kwezifazwe kanye nezokwenza. Imicimbi yazo iyabonisa ukuthi yisikali kuzindlela zokubhantu, izinto zeziliva, kanye nezokubhantsha, kubangela ukuphelelwa kwezifazwe kanye nezokwenza.