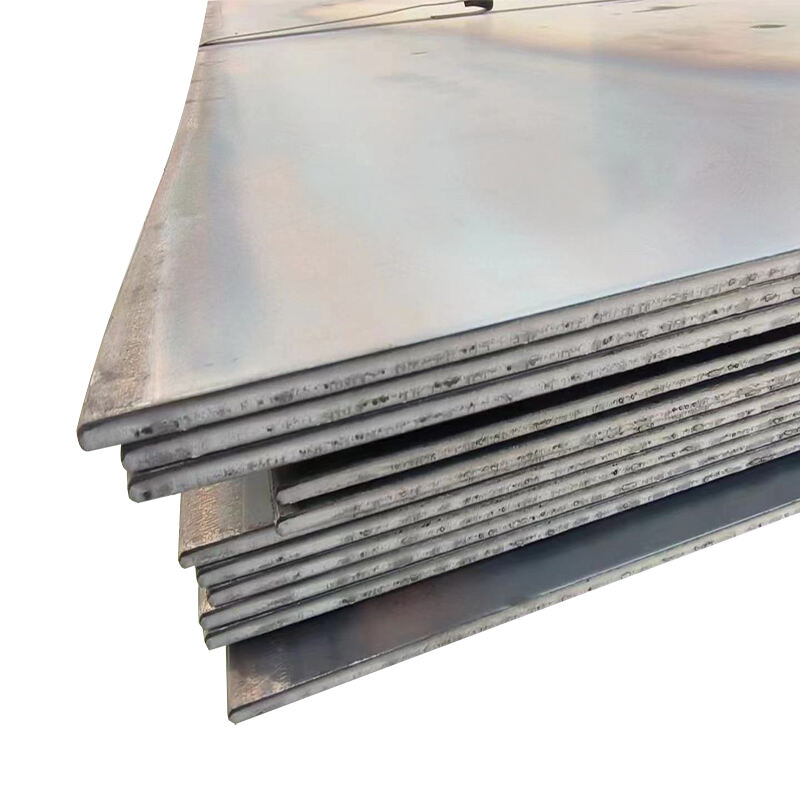

ibhara ye-mild steel

Ibha yensimbi emnene imelela isisekelo sokwakha ezimbonini zanamuhla zokwakha nezokukhiqiza. Le nto eguquguqukayo, eyakhiwe ngokuyinhloko ngensimbi enekhabhoni encane evame ukuba phakathi kuka-0.05% no-0.25%, inikeza ibhalansi enhle kakhulu yokuqina, ukusebenza kahle, nokusebenza kahle kwezindleko. Lezi zinsimbi zenziwa ngenqubo elawulwa ngokucophelela yokugoqa okushisayo eqinisekisa ikhwalithi engaguquguquki nokunemba kobukhulu. Iyatholakala ngezimo ezihlukahlukene kuhlanganise namaphrofayli ayindilinga, ayisikwele, nawayikhonkolo, amabhande ensimbi athambile asebenza njengezingxenye ezibalulekile ekusetshenzisweni kwezakhiwo, ekukhiqizeni imishini nasemsebenzini wokukhiqiza jikelele. Izici eziyingqayizivele zalesi sakhi zenza kube kuhle kakhulu ekusebenzeni kokushisela, ukusika nokwakha, kanti ukwakheka kwaso okufanayo kuqinisekisa ukusebenza okusobala ekusetshenzisweni okuhlukile. Inqubo yokukhiqiza ihlanganisa ukulawula izinga lokushisa ngokunembile kanye namazinga okupholisa, okuholela kumkhiqizo obonisa izakhiwo zomshini ezinokwethenjelwa njengokuqina okuhle kokudonsa, ukuqina, nokumelana nomthelela. Emkhakheni wezokwakha, izinsimbi ezenziwe ngensimbi emnene zisetshenziswa kakhulu ekuqiniseni izakhiwo zikakhonkolo, izinhlaka zemiklamo kanye nezinhlelo zokusekela. Ukusetshenziswa kwazo kabanzi embonini kuhlanganisa izingxenye zezimoto, ukukhiqizwa kwemishini, nokuthuthukiswa kwengqalasizinda, okwenza kube impahla ebalulekile ekusetshenzisweni kwezobunjiniyela banamuhla.