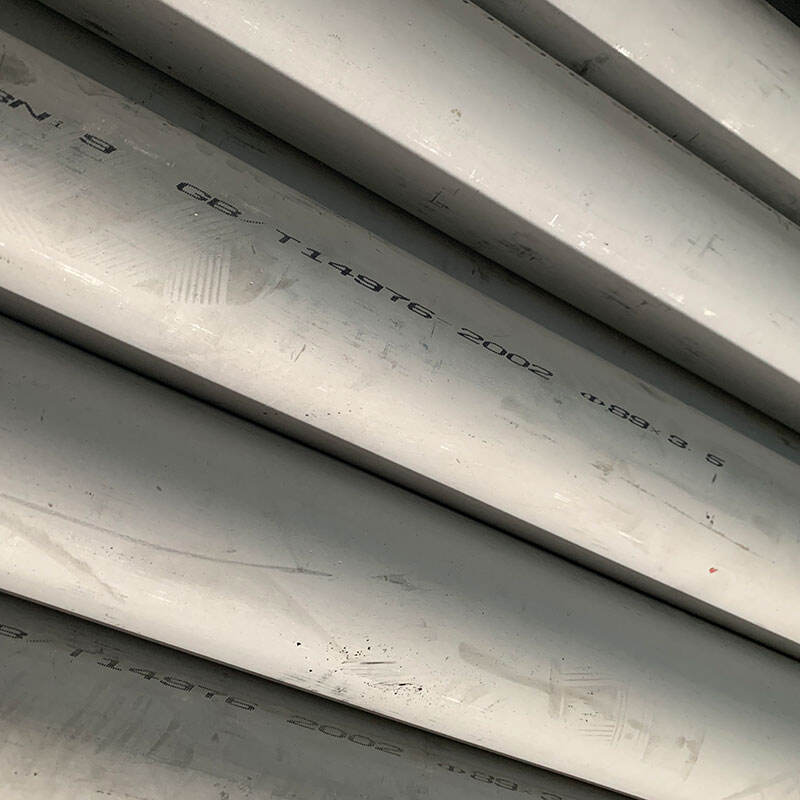

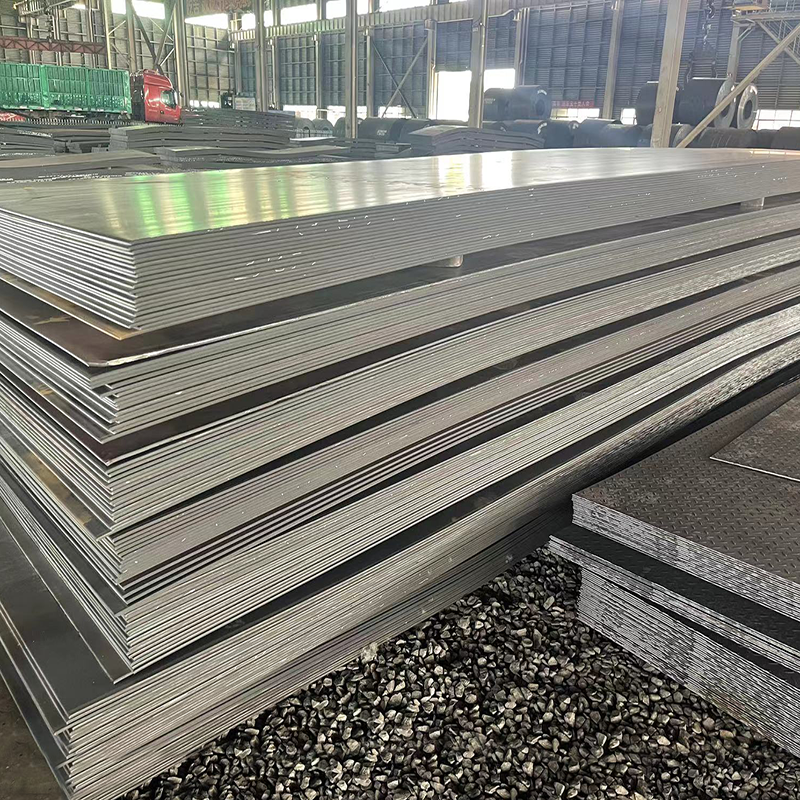

plate stainless steel

I-Plate stainless steel iyinkimbinkimbi enobuhle neyenzululwane othuthukile kakhulu ethuthukisa imicimbi ngokuphelele ngokuxhaswa kwezinhlobo zokulula, ukungena ngokulula kwezicelo, nokwandisa ubuhle. Lolu hlobo lwembula oluprecious lwenziwa ngokuphathelene kwezinhlobo zokwenza i-steel ngokusebenzisa indlela yokugcwalisa noma yokugcwalisa ngokulula, okwenza amaphela amadumbu ane-ubukhulu obulandelwe ngokuphelele nezicelo zokubhala. Ikhemikhali yalo yinhlobo yezinhlobo eziphakeme kakhulu, inikeli, nezinye izinhlobo zokudweba zokuthuthukisa izici zalo. Lezi zicathami ziyatholakala kuhlobo lwabanye, kanye ne-austenitic, ferritic, ne-martensitic, ngayinye inikwe amandla ukwenzela izidingo zokusebenzela. Izici zalo zokulula zenza ukuthi kusebenze kahle kuzo zonke izimo, zineke ukungena kwezindlela, ukungena kwezicelo, nokwandisa ukuphelele kwezimalo. Imicimbi yokwenza yamanje iyenza ukuthi ubukhona bube ngokuphelele kuzindlela ezinkulu, noma ukusebenzisa izindlela zokubhala zokuphimba kungenhisa izici ezithile njenge-ukungena kwezimalo noma izici zokungena. Ubunzima be-plate stainless steel bube yinkimbinkimbi engenalo ukungena, kuvumela ukuthi kugcinwe, kugcinwe, nokubhakwa ngokungena kwezimalo. Isenzo samanye sibophezela kuzo zonke izinhlobo, kusukela kuzindlela zokubhala nezimalo zokusebenza kuya kuzindlela zokubhakwa kwezicelo nezimalo zemedicine, lapho izimo nezimalo zokuphelele ziyinkimbinkimbi.