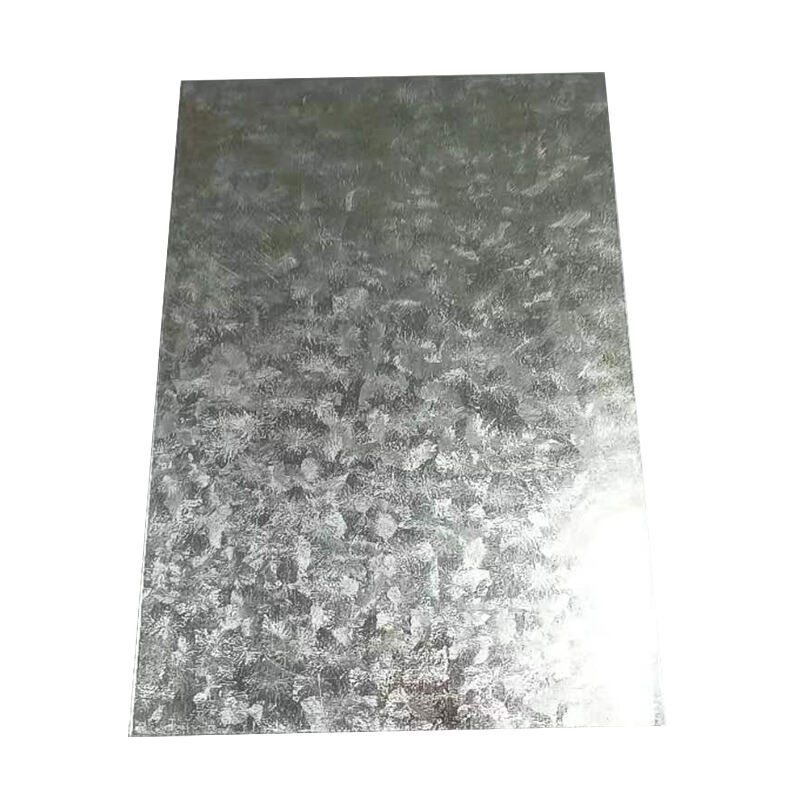

ikhoyili Yensimbi

Izinkozi zomoya zibonisa indawo ebalulekile yokwenziwa kwemateriali yomoya olwenyelwe, enguqulelwe yindlela yokubona yemali yemali esingeni esifanayo esibekwe kwi-cylinder. Le ndawo yemali yenziwa ngokuzenzekela kwezindlela zokulayisha lapho izinkozi zomoya ezinkulu kuzenzekelwa kusukela kuzoba nezobe kanye nokubekwa ngokulandelana nendlela yokugcina nokuthunyelwa. Le nkozi zingenzelwa ngokuhlanganisa amagrade, amathikhulu, nezobe, okwenza banele kakhulu kuzo zindlela zokusebenzisa ezahlukene. Iinkozi zomoya zamanje zinezabakwa zokuxilonga okuphumelelayo okwenza amathuba wabo athulwe, njengokukhulisa amathuba wokulayisha, ukulandelana nokuthula. Abasebenzisa amathuba okwenyelwa kokugcinwa kwezimali kanye nezobuchwepheshe, njengokwehlanisa, ukupaka, noma ukubhoshwa ukuze kuvunyelwe amathuba okulandela. Indlela yokulayisha kungenzeka ukulungisa ukugcina nokugcina kwezimali futhi kuthuthukisa kakhulu kwalokho kwezimali. Le ndlela yokuzenzela kudinga ukulondoloza kahle kwamandla, ukulungisa ukukhanya, nokulondoloza ukushesha kokulala ukuze kuthintanise kakhulu kwalokho kwezimali yonke indawo yinkozi.