iphepu letitanayomi lweGr5

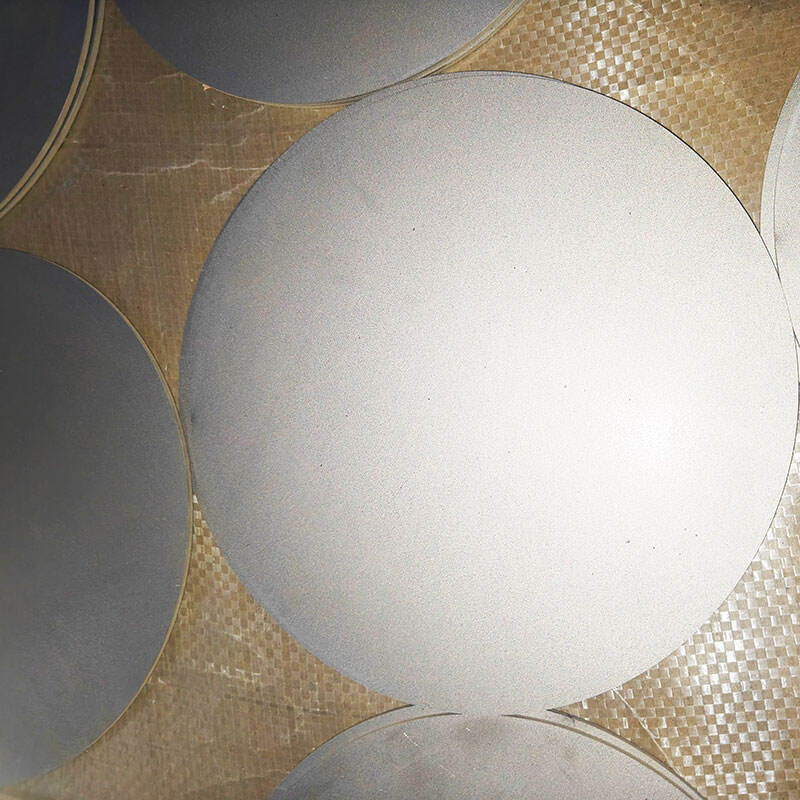

I-Plate le-Titanium Grade 5 (Ti-6Al-4V) iyatholwa kakhulu ngokuthi yindlela ephambene enkulu yokuxhumana nokuthula okukhulu. Le ndlela ephambili ihlanganisa i-6% aluminum, i-4% vanadium, ne-90% titanium, ukwenza i-plate ethuthakanye esebenza kakhulu kumisebenzi esihlengene. I-plate ikhombisa ukungcola okukhulu kwe-corrosion futhi ithuthakanye ukuphepha kwezinhloso kakhulu zokulingana, kusuka kumakhiwo amancane kuya kumaqondo amaphezulu. Ikhono leyo yokuthula ngokuphindwa kwegcinwa kuye kuyakhiwa kakhulu kumisebenzi yesivumo, noma yisiphi isimiso, nezinhlanzi. Inhloso yokuthula yayo engcola kakhulu futhi ukuthuthukiswa okukhulu kwe-biocompatibility, ukwenza yona indlela engcono kuma-implants amedicali nezinsiza zokuchitha. Nge-tenstle strength ekuhambisana kwe-895 kuya kuma-1000 MPa futhi i-yield strength ibi 828 MPa, i-titanium plate gr5 ikhomba ukusebenza okuthulayo kumisebenzi esihlengene. Inhloso yayo engcola yokuthanda kwezindlela zokuthula kuyakhiwa ukuphepha kwezinhloso, futhi amanye amaphroperty ayi- non-magnetic akuyakhiwa engcono kumisebenzi esilandelwe yama-electronic. Lezi plate zingakhiwa ngemitha le-thickness nezinhloso ezahlukene ukwenzelana nezidingo zokusebenza, ukunikeza ukuthuthukiswa kwezinhloso nezindlela zokusebenzisa.