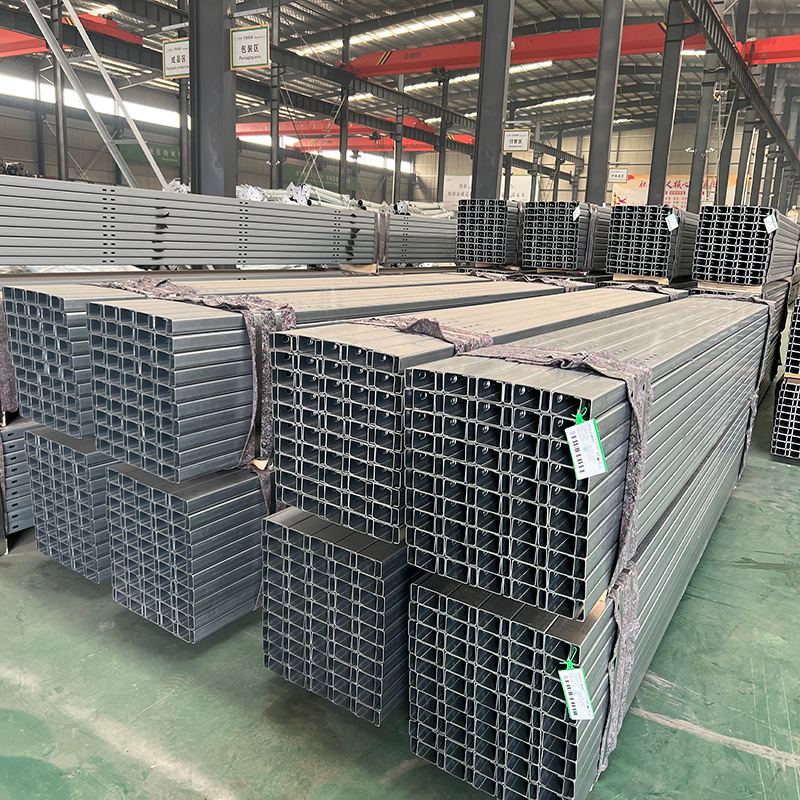

galvanized i beam

A galvanized I beam represents a crucial advancement in structural engineering, combining the inherent strength of traditional I beam design with superior corrosion resistance through the galvanization process. This structural element consists of two horizontal flanges connected by a vertical web, creating the distinctive I shaped cross section, with the entire surface protected by a zinc coating. The galvanization process involves immersing the steel beam in molten zinc at approximately 840 degrees Fahrenheit, creating a metallurgical bond that forms multiple zinc iron alloy layers. This treatment provides comprehensive protection against rust and corrosion, significantly extending the beam's service life. These beams are extensively used in commercial and industrial construction, bridge building, and heavy duty support structures. Their load bearing capacity is exceptional, particularly in applications requiring resistance to both vertical and lateral forces. The galvanized coating typically achieves a thickness between 3.9 and 5.0 mils, providing decades of maintenance free protection even in challenging environmental conditions. The combination of structural integrity and corrosion resistance makes galvanized I beams particularly valuable in coastal areas, chemical plants, and other corrosive environments.