hot rolled coil

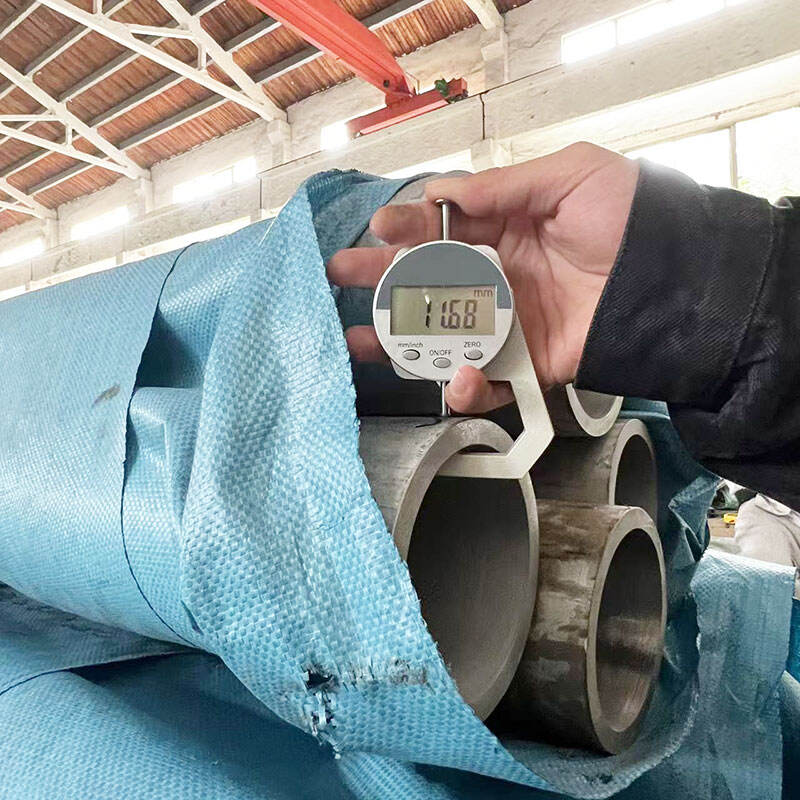

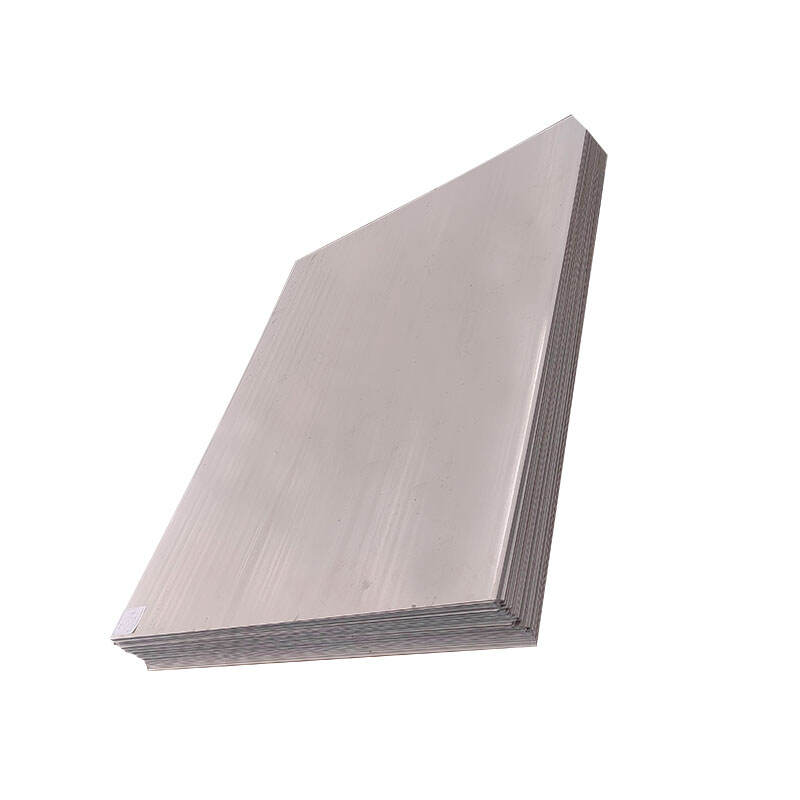

Hot rolled coil represents a fundamental steel product manufactured through a high-temperature rolling process, typically above 1,700°F. This manufacturing method involves heating thick steel slabs to extreme temperatures before passing them through a series of rollers that progressively reduce their thickness to create the desired dimensions. The process results in a product that exhibits consistent material properties throughout its structure, making it ideal for various industrial applications. Hot rolled coil features a characteristic dark gray surface with slightly rounded edges and a scaly finish, which is a direct result of the oxide formation during the heating and rolling process. The material's versatility is demonstrated through its wide range of thickness options, typically ranging from 1.2mm to 25mm, and width variations that can extend up to 2,000mm. These coils serve as essential raw materials in numerous industries, including construction, automotive manufacturing, industrial equipment production, and infrastructure development. The product's mechanical properties, such as excellent formability and weldability, make it particularly suitable for applications requiring structural strength and durability. Additionally, hot rolled coil offers cost-effective solutions for large-scale manufacturing operations due to its efficient production process and minimal post-processing requirements.