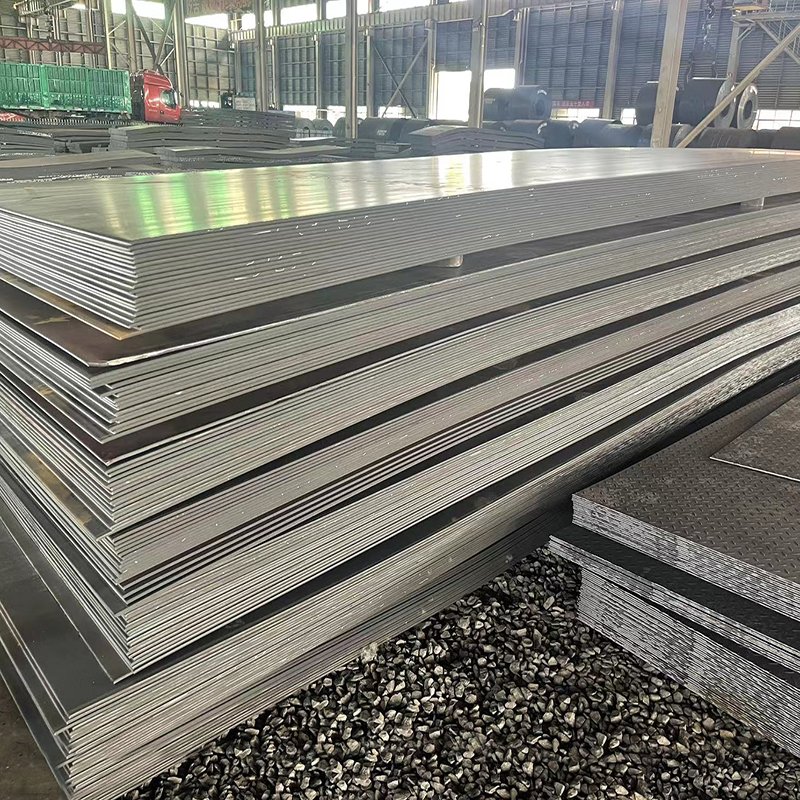

karbon polad təbəqə

Karbonlı polad vərəqi möhkəmlik, davamlılıq və qiymət səmərəliliyini birləşdirən çox yönlü və geniş istifadə olunan metal materialıdır. Dəmirin karbonla ərintiləşdirilməsi prosesinin nəticəsində istehsal olunan bu vərəqlərin tərkibində adətən 0.05% -dən 2.1% -ə qədər karbon olur. Karbonun miqdarının dəqiq nəzarəti istehsalçıların müxtəlif mexaniki xassələrə malik vərəqlər istehsal etməsinə imkan verir. Bu vərəqlər müəyyən qalınlıq tolerantlıqları və səth emalı əldə etmək üçün qızdırmaq, soyutmaq və istilik müalicəsi kimi keyfiyyətli nəzarət proseslərindən keçirilir. Karbonlu polad vərəqləri əla qaynaq, formalamaq və emal etmək mümkündür, bu da onları müxtəlif sənaye tətbiqləri üçün ideal edir. Onlar yüksək dartı möhkəmliyi və akma həddi hesabına konstruksion tətbiqlərdə yaxşı işləyir və müxtəlif iş şəraiti altında etibarlı performans təmin edir. Materialın xassələri onu mexaniki gərginliyə, temperatur dəyişikliklərinə və ətraf mühit amillərinə qarşı davamlı edir və uzun müddətli etibarlılığı təmin edir. Müasir istehsalda karbonlu polad vərəqləri tikintidə, avtomobil sənayesində, sənaye avadanlıqlarında və istehlak mallarının istehsalında əsas komponentlər kimi xidmət edir. Onların çox yönlü olması müxtəlif bitirmə variantlarına, o cümlədən sintətik örtük, rəngləmə və ya toz boyalarla örtük əlavə etməyə imkan verir, bu da korroziyaya davamlılığı və estetik cəlbediciliyi artırır.