umkhuhlu wendlovu oluhloleniwe

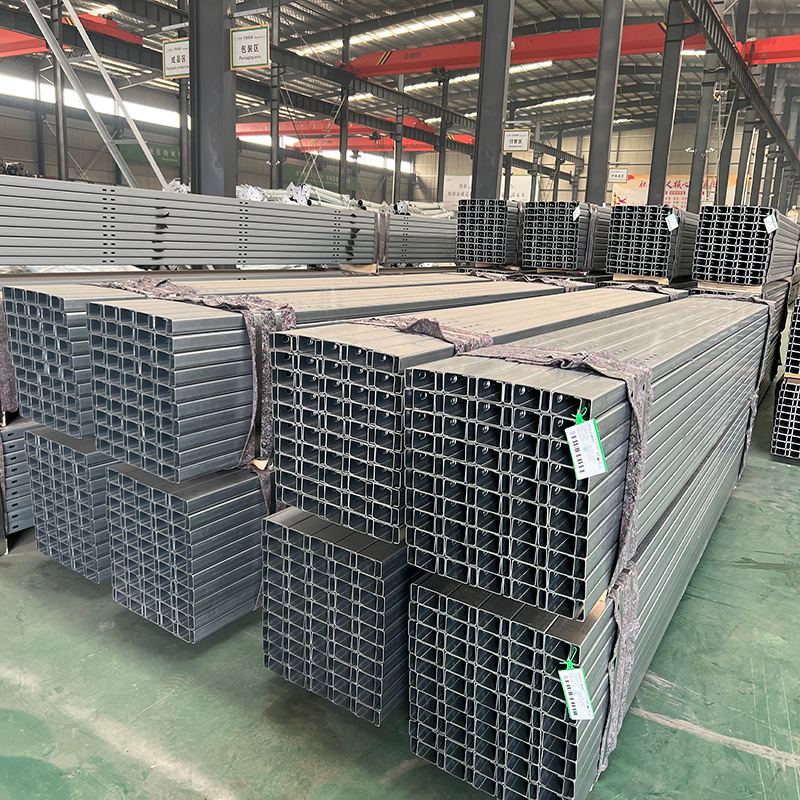

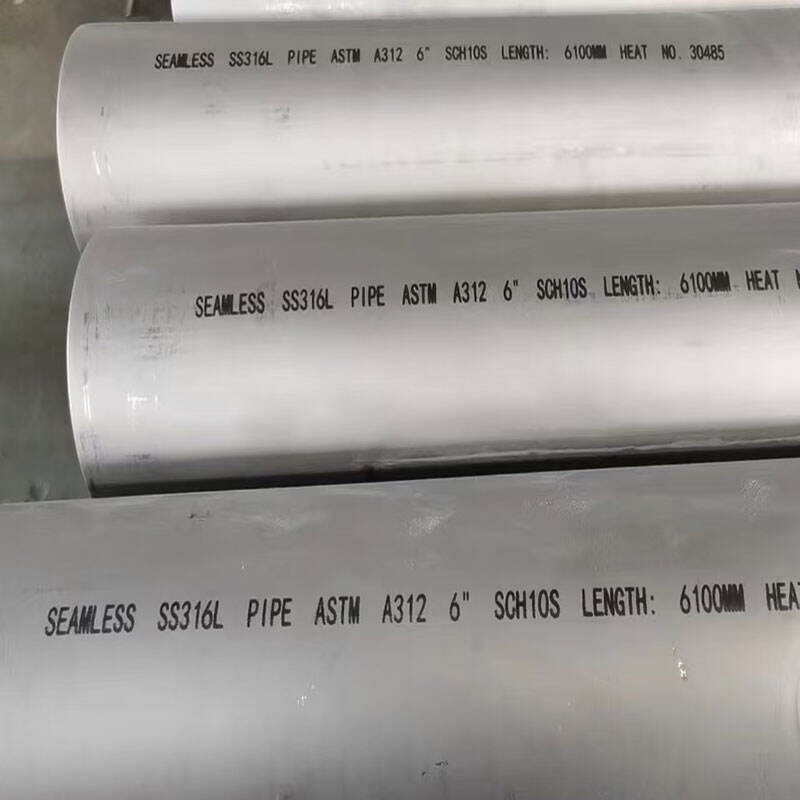

I-beam elikagaleyo luyindlela ebalulekileyo kumendini wezokwelapha, ehlanganisa ubuchule obukhona kwi-beam le-I edileni nekuhlanjwa okuningi kwezicorrosion ngokusebenzisa indlela yekagaleyo. Lo moya wezokwelapha unemigca emibili yemaphakathi edlule ngaphakathi kwaye iyaholwa ngokuhambelana, ukwenza i-I ngokweqileyo, ngelixa sonke isayizi esiyihlawuliwe ngokuhambisa izinkco. Indlela yekagaleyo iyahlula ukuthiwa kwi-beam yesilika kwi-zinkco ezilandelanayo kwiindlela ezingama-840, ukwenza ubudlelwane obukhona phakathi kwezilika nezinkco obungenayo amatholiso amabili. Le ndlela inika ukuphephelwa okupheleleyo kwi-rust nezicorrosion, ukuba khawuleza ubude bokuphila kwe-beam. Ezi beam zisetyenziswa ngokukhawuleza kwiinkqubo zokubulala, ukwenza iindleke, kunye nezinto ezingeyo zokuthutha. Iindlela zabo zokuthatha izixa ziyinkimbinkimbi, ngqo kakhulu kwiindlela zokusebenzisa ezingadinga ukuthibela kwiimeko zokubuka kunye nezokugqibela. Ikhokelo lezinkco kuvumelwa ukuba liphakathi kwi-3.9 kunye ne-5.0 mils, ukunika amaminithini angama-10 okuphephelwa ngaphandle kokulungiswa nangona kwiimeko ezingeyo. Ukuchongwa kwezokwelapha kunye nezicorrosion kuyenza i-beam zase-I zikagaleyo zibaluleke kakhulu kwiindlebeni zokhewula, iindlebeni zokuchithwa, kunye nezinye iindlebeni ezingeyo.