isiye eshaped ngamagcali

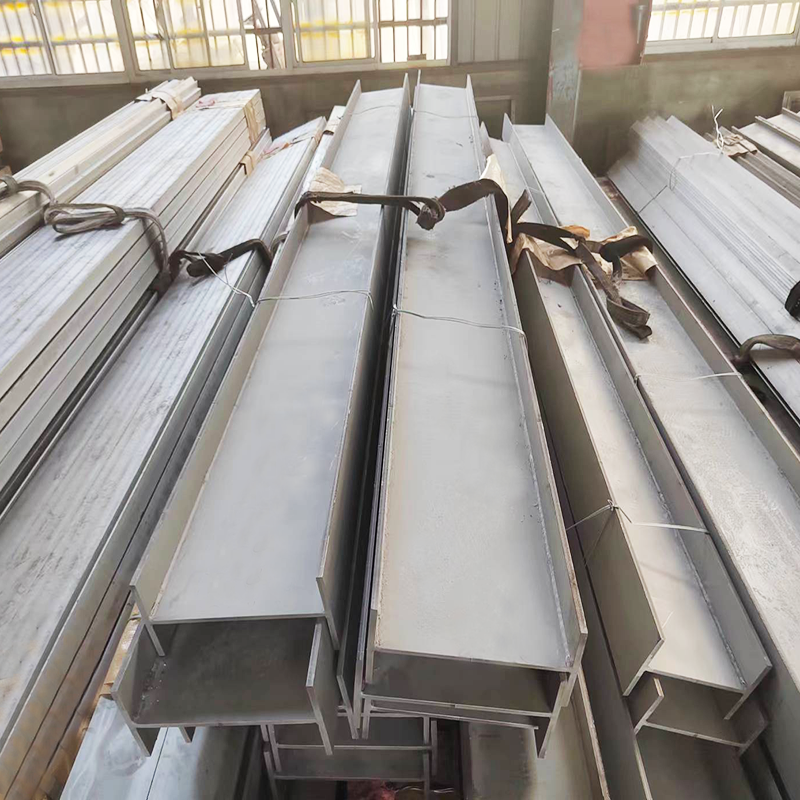

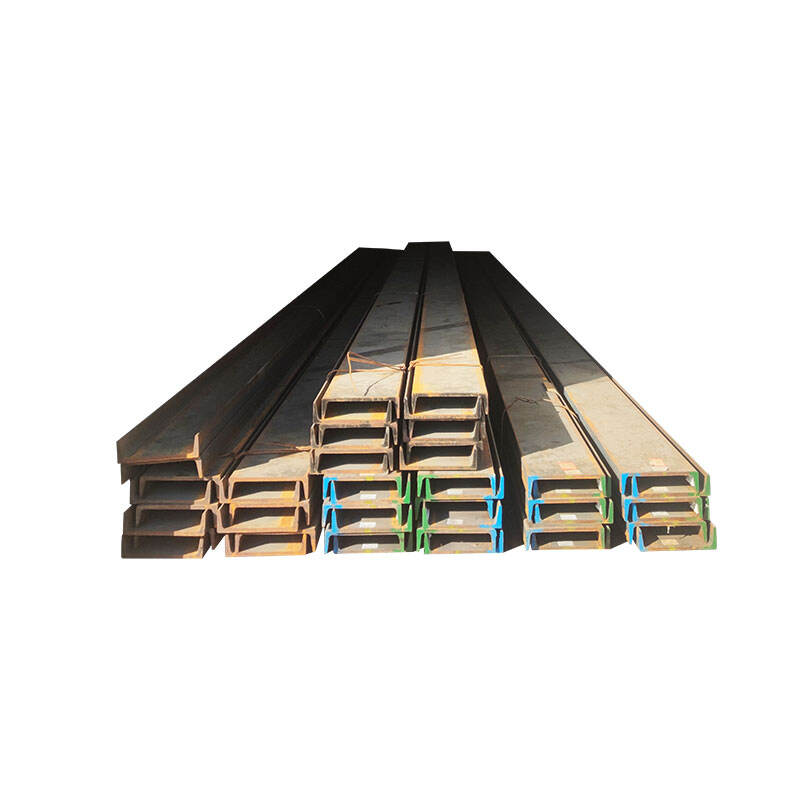

I-steel esixhakileyo, bekuthiwa ngokuba yi-H beam okanye i-wide flange beam, iyinkqubo ebalulekileyo kwiimeko nezixhobo zokugcwala ngokuqinisekileyo. Le profile steel edolophakathi inama-flange amabini ambili aphakathi kwaye aqondakalisa i-vertical web, ukwenza kwaye ithathe i-H esixhakileyo. Iqondo lokhu lichaza ukuba linokulayisha ngokukhulu nangona linemali ephakeme kwaye inezakhono elithile. I-H shaped steel yenziwa ngokuzenzekelayo kwiimeko eziphumeleyo ukuze iimeko zokugcwala zibe ngqo. I-geometri yalo iyakuvumela ukuba inqanawe ngokuphendula kwiindlela zokubhuka ngaphambili web nangona inikeza amandla angcono aqwalaselo nezakhono ukugqwalisa. Ubunzima bendawo kunye nenqanakalo yalo enokunika kwiimeko, iibhamu, kunye nezixhobo zokudityaniswa kwiimeko yokuwothwa nezindawo zokusebenza. Ikhompi yezimoto ngokuvumela i-structural steel engekhona, ukunika ubunzima kunye nobulungiswa ngokulinganayo. Iintambo zokwenza ngokuqinisekileyo zinika amandla ukulawulwa kwezibalo kunye nezixhobo zokugqibela, okwenza ukuba iintambo ziyilandela iindlela zokubaluleka. I-H shaped steel isetyenziswa ngaphandle koko kwiimeko yokuwothwa kwiimeko yokubhuga, iindawo zokuthsupporta izixhobo, kunye nezixhobo ezikhankqwayo, ukwenza yinto enalungelo kwiimeko zokudityanisa ngokuqinisekileyo.