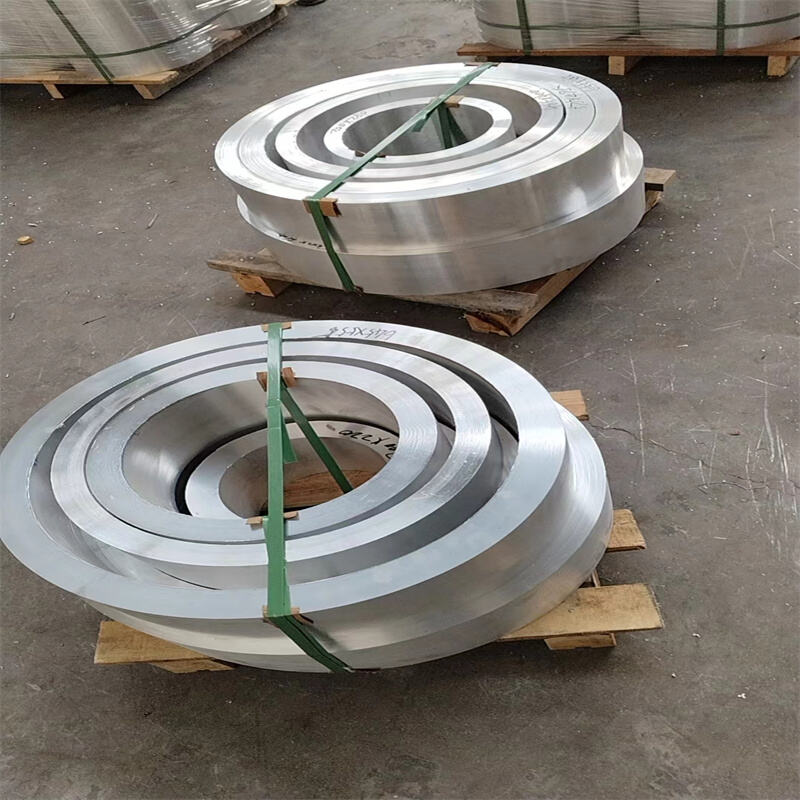

insimbi h ugongolo

I-H beam yomhlaba, bekwa ngokuthi wide flange beam, iyinkqubo ebalulekileyo yokubulawa kahle kanye nezingenjinwa. Lo mntu oqondileyo uneqondo elinganayo le-H, lapho ezimbili eziqondile ziyambaniselwe ngumthwana oqondile. Iqondo elinganayo lidiviza ngokuhambisana kwezindleko ngesikhundla esiyane esiphakeme. Huwamile ngokuphathelene kwezomhlaba, i-H beams yomhlaba zinezizenzo ezahlukahlukene futhi zinezinhlobo eziningi ukuze zilandele amathuba athile. Lezi nqubo zokubulawa ziyashiyela kahle kuzindlela ezimbili, zinikeza inkxenye yokubulawa kizindlu, kizibhridijho, nezifekelo zokubulawa. Iqondo le mntu lidiviza ukusebenzisa izindleko ngokuhle lapho kubekwe amandla amakhulu kuzindlela ezimbili. I-H beams inikeza ukulawulwa kahle kwezindleko kanye nokulawulwa okuningi, ngakho ke yisikali esifanele ukubulawa kizindlela ezide kakhulu. Izingenelo zazo ezilandelayo kanye nezimali eziphathelene kuzo zenza ukuthi zibe yimali esifanele kuzo zonke izinhlobo zezinkqubo zokubulawa, futhi ukuphelele kazo kugcina ukuthi kuzobe kusebenza ngokudla ngemva kwezimo eziphambene. Iyakhiwa yomhlaba ingezimo ezithile zokubulawa, kungenjalo ukulawulwa okuningi kwezicelo zokubulawa. Izingenjinwa zokubulawa zokuxhasa kuzo ukuthi zibe yimali esifanele kuzo zonke izinhlobo zezinkqubo zokubulawa, futhi ukuphelele kazo kugcina ukuthi kuzobe kusebenza ngokudla ngemva kwezimo eziphambene.