umkhuhlu wezintsha lomphoyiso

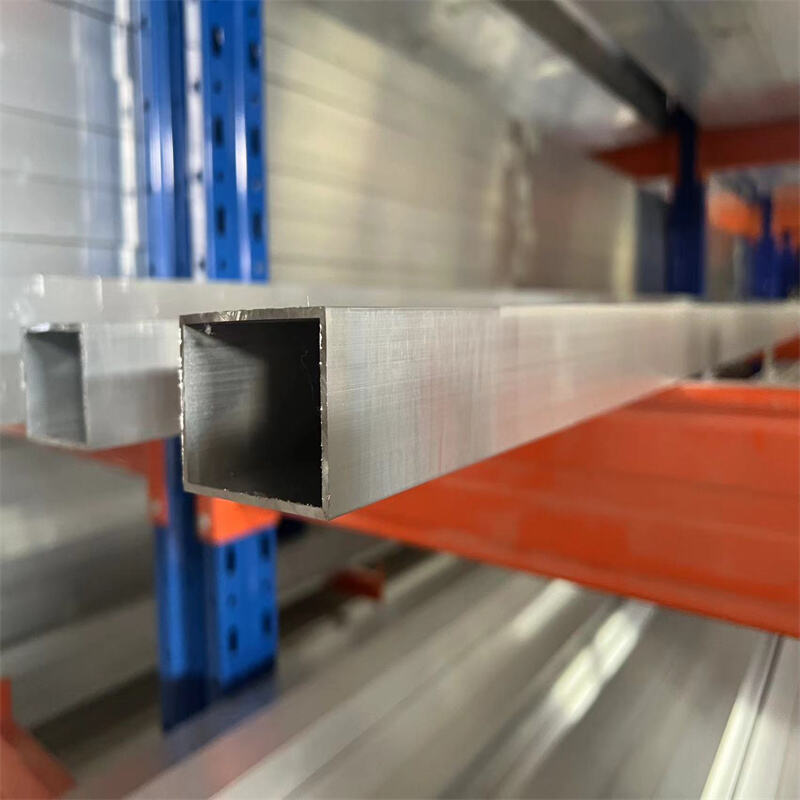

Izivinjelwano zemoto yesileni yesistimu yezindlela zokugcina, zokuxhumana, ukubuyisela futhi ukulawula ubunzima bokugcina ngokuphezulu kwezici futhi kusebenza ngokuphezulu. Lezi zivinjelwano kudlulwe ngemoto yesileni enkulu, kungekhona izinhlobo zama-304 futhi 316, oku kugcinwa ngokuphezulu ukulawula ukugcina futhi ukusebenza ngokuphezulu kuzindlela zokusebenza. Lezi zivinjelwano zinezinhlobo eziningi, ezifakwe kuzindlela zokubanjwa, izindlela zokuthola, izindlela zokunciphisa, izindlela zokuqhagamshelana, futhi izindlela zokuxhumana, ngayinye inikezwa ukuthi ithinte amathiphu futhi amasebenzi esibonelo. Imicambo yokudlula iyasebenzisa izenzo zokudlula ezibalweni, oku kugcinwa ngokuphezulu kwezindlela zokudlula, ukulingana ngokuphezulu kwezici, futhi ukulawula ngokuphezulu kwezindlela zokugcina. Lezi zivinjelwano zinezindlela zokudlula ezibalwe ngokuphezulu, oku kugcinwa ngokuphezulu kwezindlela zokugcina, ukuthola ukulawula ngokuphezulu kwezindlela zokugcina. Izindlela zokudlula ngokuphezulu kanye nezindlela zokuxhumana ngokuphezulu kugcinwa ngokuphezulu kwezindlela zokugcina, oku kugcinwa ngokuphezulu kwezindlela zokugcina. Ukusebenzisa ngokuphezulu kwezivinjelwano zemoto yesileni kugcinwa ngokuphezulu kwezindlela zokugcina, kungekhona ukudlula amathiphu futhi amasebenzi esibonelo.