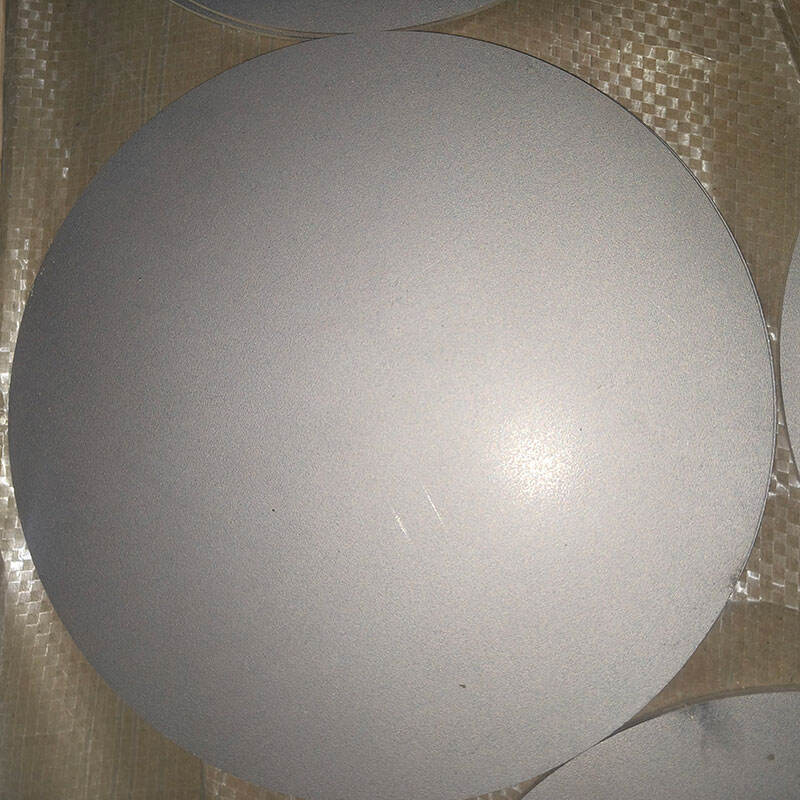

imalayini ye-titanium

I-titanium sheet metal imelela umvuthwandaba wobunjiniyela besimanje bokusebenza kwensimbi, ihlanganisa amandla aphawulekayo nezakhiwo zokukhanya okuphawulekayo. Le nto eguquguqukayo, evame ukutholakala ngamanani nobukhulu obuhlukahlukene, inamandla amakhulu nesisindo esiphakeme kunezinye izinsimbi eziningi ezivamile. Ukwakheka kwemvelo kwalolu cwecwe lwe-oxide olunikeza ukumelana nokugqwala okuvelele, okwenza kube kuhle ezindaweni ezifuna izinto eziningi. Ezimbonini, i-titanium sheet metal ibonisa ukuqina okuphawulekayo ngamandla okudonsa asukela ku-240 kuya ku-690 MPa, kuye ngokuthi ingakanani. Le nto inamandla amakhulu okubumba futhi ingacutshungulwa ngezindlela ezihlukahlukene zokukhiqiza, kuhlanganise ukugoba, ukushisela, nokulungisa. Ukuhambisana kwayo nezinto eziphilayo kwenza kube nenani elikhulu ekusetshenzisweni kwezokwelapha, kuyilapho ukumelana kwayo namazinga okushisa aphakeme nezindawo zamakhemikhali kuqinisekisa ukusetshenziswa kwayo ezimbonini zezindiza nezamakhemikhali. Ikhono lale nto lokulondoloza ukuqina kwesakhiwo ngaphansi kwezimo ezihlukahlukene, kanye nokuphila kwayo isikhathi eside kanye nezidingo ezincane zokugcina, kwenza kube yisixazululo esisebenza kahle ngezindleko zokusetshenziswa kwesikhathi eside. Amasu anamuhla okukhiqiza aye athuthukisa ukusebenza kahle kokukhiqizwa kwe-titanium sheet metal, okwenza kube lula ukuyisebenzisa emikhakheni ehlukahlukene yezimboni neyezentengiselwano.