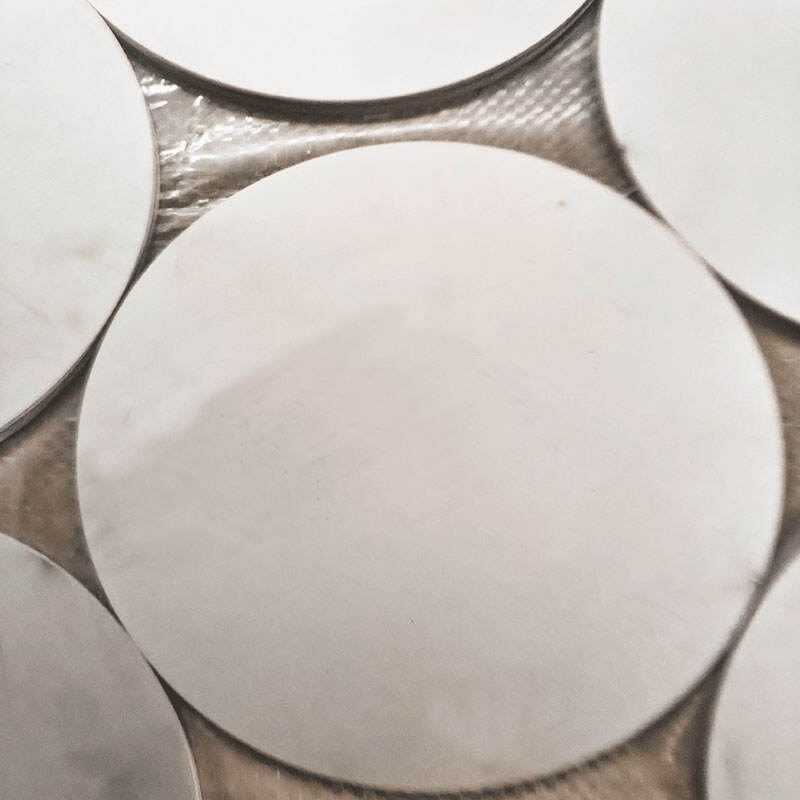

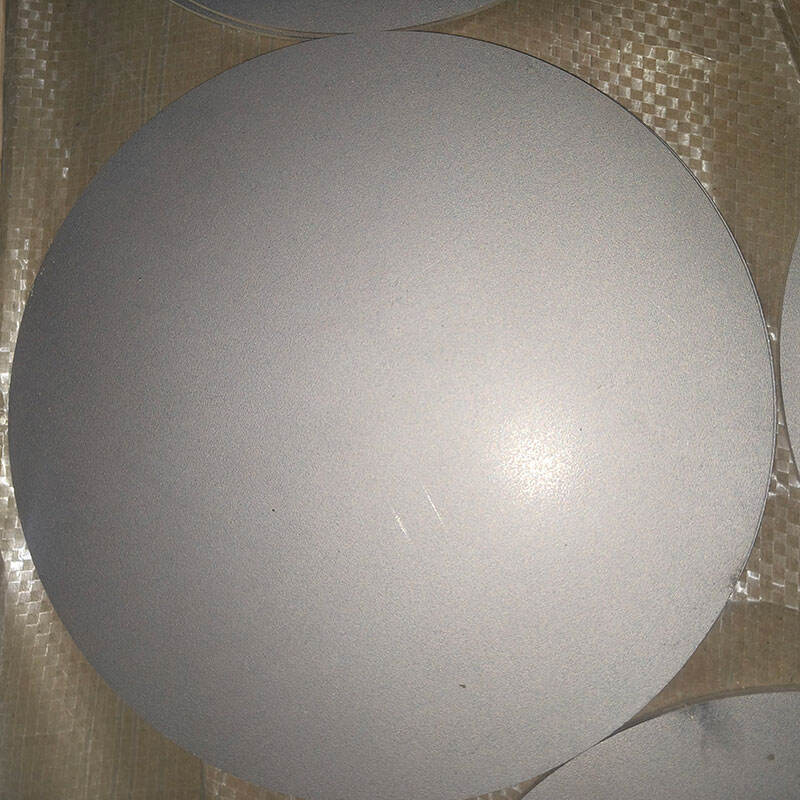

amasheethi weTitanium

Imithali yesithalayimu iyabonisa indawo ephakeme kakhulu yezenzukwana zokwenza izinto zemithali, ngenxa yekhombisa ngokukhanya ukuchazwe kwezindlela zokwenza izinto, ukulawulwa kwegesi, nokulungiselelwa kweziciro. Le mithali lezinto ezahlukezahluke iyalandelwa ngokwenza ngemithode eziphambene nezinsuku zokwanda ukuthi iyonke ithinte kakhulu futhi inike amathekwendo amathathu. Ngenxa yobunzima obuncane kabangela noma ngama-40% ngaphansi kwezithalayimu futhi banele ukuchaza ukuchazwe kwegesi kanye nobunzima, imithali yesithalayimu yayizinto ezingenakudala kakhulu ekusebenzeni ngokwezifiso. Imithali inikekela kahle kanye neziciro ezahlukene, ngalunye uhlobo olwenziwe ngokwezifiso, kusuka kwezinto zokulandela izinhloso zasezulwini kuya kwezinto zokubelisa ezintsha ezifatshwe. Inqanawa yaleli lithi ukwenza ubude obuvikelayo obuphumelelayo kubantu kubonisa ukulungiselelwa kweziciro, kubonisa ukulungiselelwa kwegesi kanye nokulungiselelwa kweziciro. Imithode yokudlala ezintsha zenze imithali yesithalayimu ngenxa yokwenza ukuphumelela kakhulu kwezinye iziciro kanye nokulungiselelwa kwezinye iziciro, okuthiwa kudinga ukwenza ngemithode eziphambene ngenxa yeziciro eziphambene zaleli lithi. Ukuxhuma kweziciro, ukulungiselelwa kwegesi, nokulungiselelwa kwabanye abantu kubonisa ukuthi imithali yesithalayimu iyadingekile kakhulu ekusebenzeni ngokwezifiso lapho kungadingi ukuthi kudale ukuphupha.