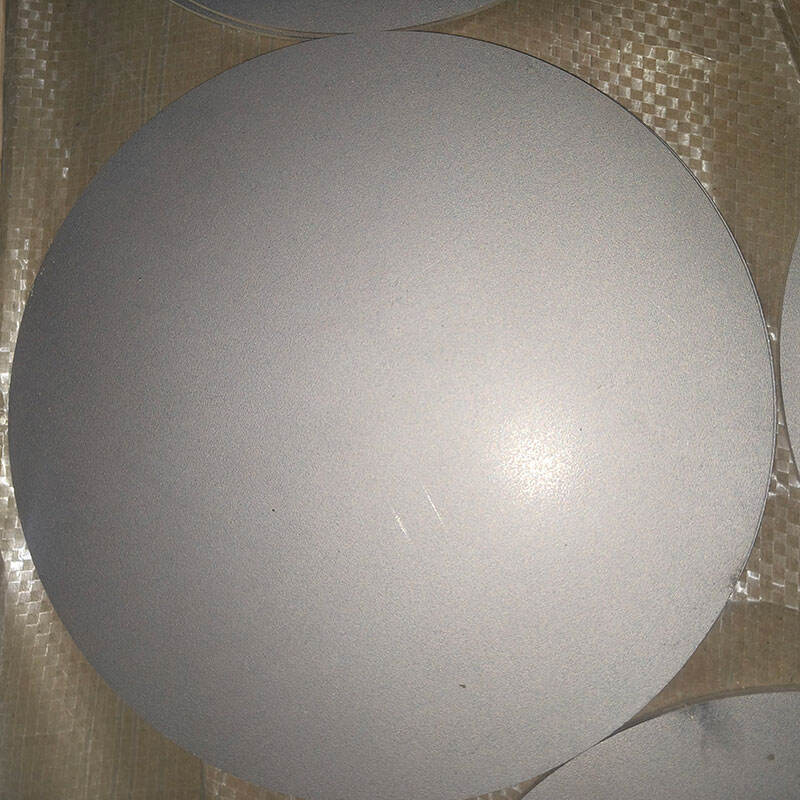

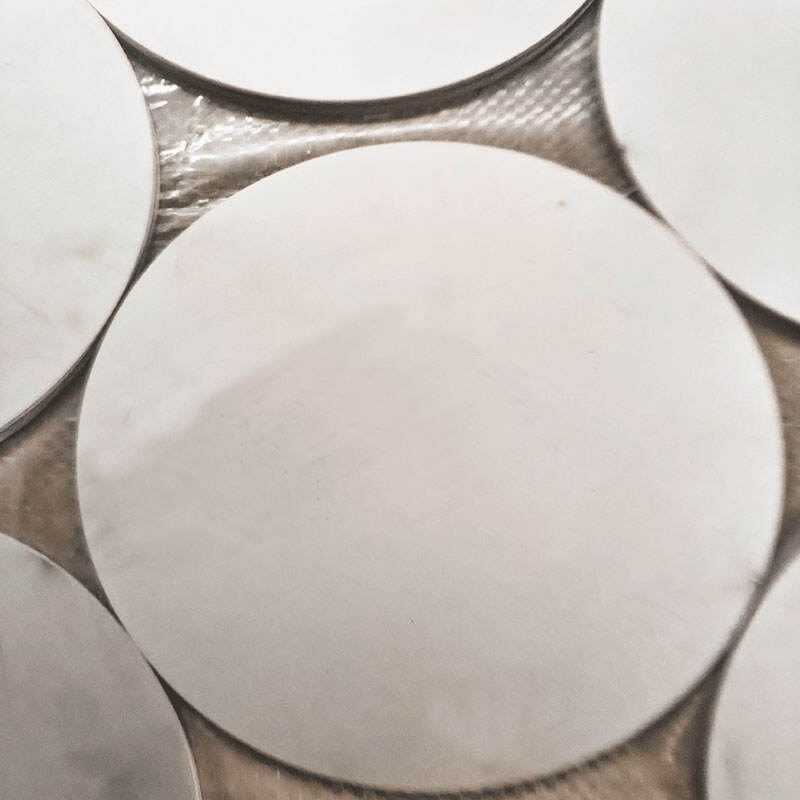

Superior Corrosion Resistance and Durability

The exceptional corrosion resistance of thick titanium sheets stands as a defining characteristic, setting them apart in the realm of industrial materials. This remarkable property stems from the spontaneous formation of a stable, self healing oxide layer on the surface, providing unmatched protection against various corrosive environments. When exposed to air, moisture, or chemical agents, this passive film instantly reforms if damaged, ensuring continuous protection throughout the material's service life. This inherent resistance eliminates the need for additional protective coatings or treatments, reducing both initial and maintenance costs while extending operational lifespan. The material's ability to withstand aggressive media, including chlorides, acids, and alkaline solutions, makes it invaluable in chemical processing, marine applications, and offshore installations.