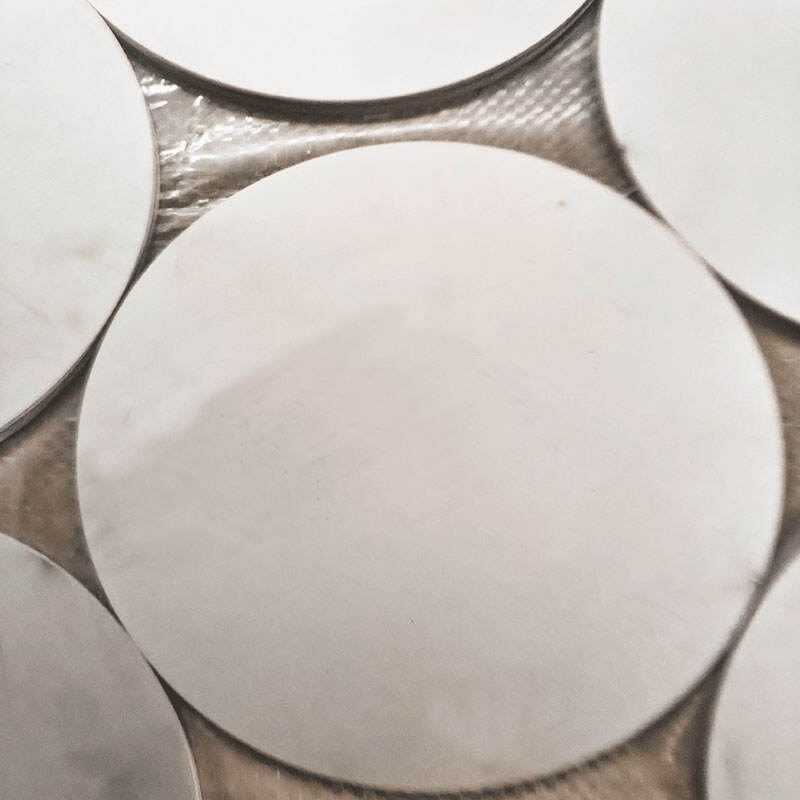

titanium sheet grade 5

Titanium sheet grade 5, also known as Ti-6Al-4V, represents the gold standard in high-performance titanium alloys. This versatile material combines exceptional strength with remarkable lightweight properties, making it a preferred choice across various industrial applications. The alloy consists of 6% aluminum and 4% vanadium, with titanium as the base metal, resulting in a material that offers an outstanding strength-to-weight ratio. With a tensile strength ranging from 130,000 to 170,000 psi, this grade of titanium sheet demonstrates superior resistance to corrosion and excellent performance under extreme temperatures. The material maintains its structural integrity in temperatures ranging from -350°F to 1,000°F, making it invaluable in aerospace and medical applications. Its biocompatibility and resistance to bodily fluids have established it as a crucial material in medical implants and surgical instruments. The grade 5 titanium sheet also exhibits exceptional fatigue resistance and crack tolerance, ensuring long-term reliability in critical applications. These properties, combined with its excellent machinability and weldability, make it an ideal choice for components that require both strength and precision manufacturing.