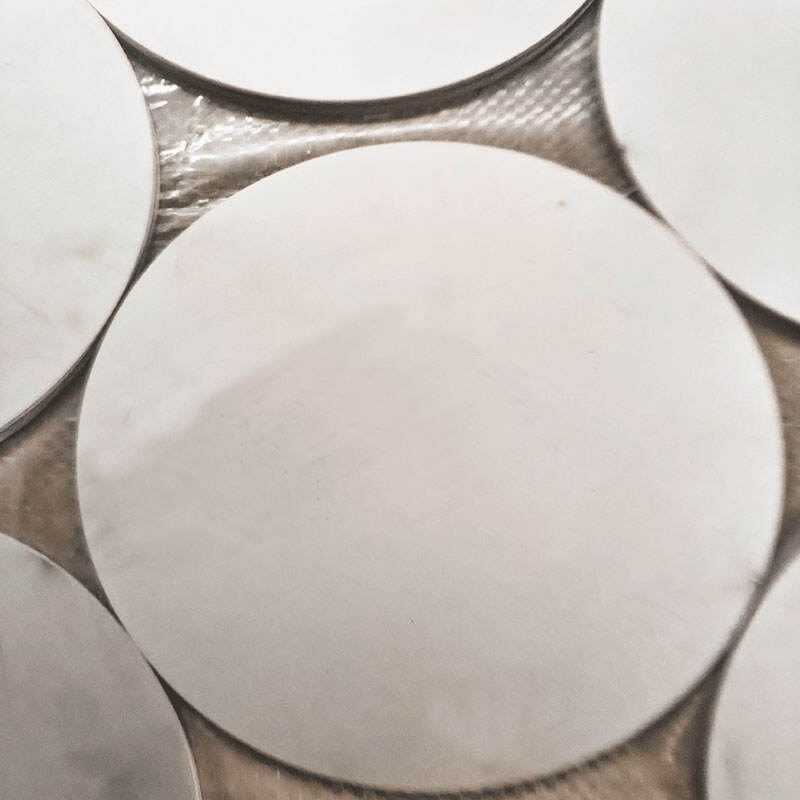

titanium sheets

Titanium sheets represent a pinnacle of modern metallurgical engineering, offering an exceptional combination of strength, lightweight properties, and corrosion resistance. These versatile metal sheets are manufactured through advanced processing techniques that ensure consistent quality and precise specifications. With a density approximately 40% lower than steel while maintaining superior strength-to-weight ratios, titanium sheets have become indispensable in various high-performance applications. The sheets are available in different grades and thicknesses, each optimized for specific use cases, from aerospace components to medical implants. The material's natural ability to form a protective oxide layer makes it highly resistant to various forms of corrosion, including saltwater exposure and chemical degradation. Modern manufacturing processes enable the production of titanium sheets with exceptional surface finish and dimensional accuracy, ensuring they meet the most demanding industrial standards. These sheets can be fabricated using conventional methods including cutting, welding, and forming, though special techniques may be required due to the material's unique properties. The combination of mechanical strength, chemical stability, and biocompatibility makes titanium sheets particularly valuable in critical applications where failure is not an option.