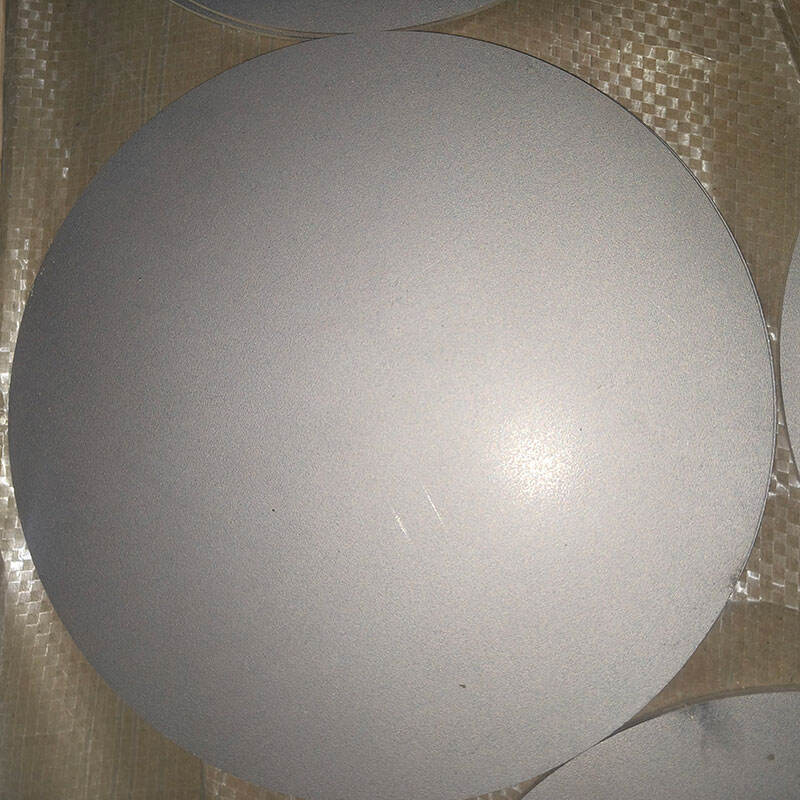

titanium sheet metal

Titanium sheet metal represents a pinnacle of modern metallurgical engineering, combining exceptional strength with remarkable lightweight properties. This versatile material, typically available in various grades and thicknesses, offers an impressive strength-to-weight ratio that surpasses many conventional metals. The material's natural formation of a protective oxide layer provides outstanding corrosion resistance, making it ideal for demanding environments. In industrial applications, titanium sheet metal demonstrates remarkable durability with a tensile strength ranging from 240 to 690 MPa, depending on the specific grade. The material exhibits excellent formability and can be processed through various manufacturing methods, including bending, welding, and machining. Its biocompatibility makes it particularly valuable in medical applications, while its resistance to extreme temperatures and chemical environments ensures its utility in aerospace and chemical processing industries. The material's ability to maintain structural integrity under diverse conditions, coupled with its long service life and minimal maintenance requirements, makes it a cost-effective solution for long-term applications. Modern manufacturing techniques have enhanced the production efficiency of titanium sheet metal, making it increasingly accessible for various industrial and commercial applications.