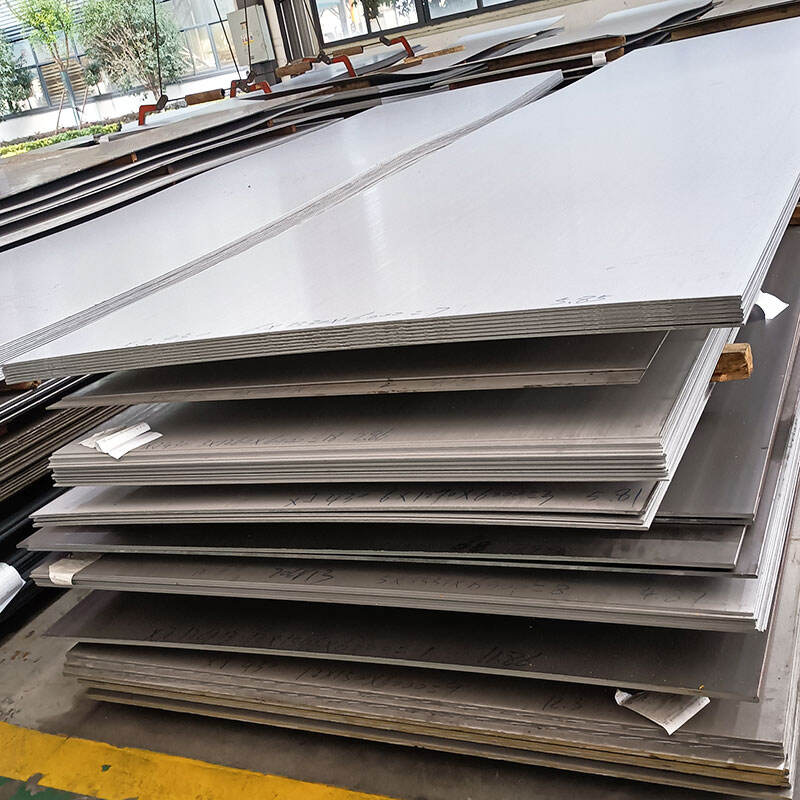

amasheba yezintathu lwe-316l

i-316L stainless steel sheet iyindlela ephumelelayo yematerial engenamakhemikhali e-austenitic engenamakhemikhali eshiseni kakhulu ngokuthula kwayo kanye nezisebenzayo ezahlukeneyo. Le alloy enobukhulu obuphumelelayo ibonakala ngokuthula okuphansi (ubude bokugcina 0.03%) kwaye yenziwe ngaphakathi kwe-molybdenum, okwenza yona ngokuthiwa ngokuthula kwayo kwiimeko eziphambene. Le material iyindlela ephumelelayo kwiimeko ezingaphandle kwaye zisebenzisa amachemikhali kanye nezixhobo zokwenza izinhlelo ngokuthula kwayo kuma-chlorides nakuma-acids. I-316L grade enobukhulu obuphansi bokhuphuka kakhulu kwayo kwiimeko zokugcina, kuyakunceda ukuthula kwayo kwiimeko zokugcina. Le sheet zinikwa kwiindlela ezahlukeneyo zokubona, kusuka kwi-polished kuya kuma-matte, ukunceda ukuthunyelana nezidingo zokusebenza kanye nezokubonakala. Inobukhulu obukhulu bokwenza amaphormu amakhulu ngelixa kuthutha isiqhutywa. Ngenjongo yokusebenza kuya kusuka kwiimeko ezingaphakathi kuya kuma-870°C, iyasebenza kwiindlela ezahlukeneyo zokusebenza. Iziphumo ezilungiselelweyo kanye nezokunceda ukuthiwa kakhulu kwenza ukuba yisicelo esifanelekileyo kwiimeko ezingenamakhemikhali, kwaye yinto ethuthakaleyo yokuba yenziwe kabusha ngaphandle kokulahleka kwayo.