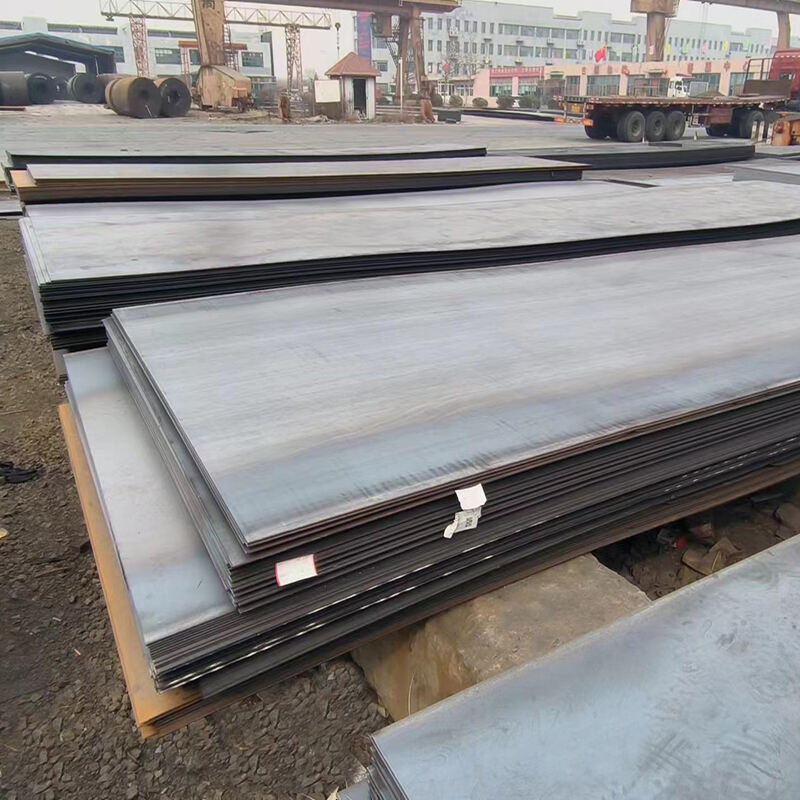

brushed stainless steel sheet

I-Brushed stainless steel sheet ikhomba umsebenzi osheqelekileyo wesivinini esihlukileyo okuphathelana ngokuphezulu nokulula kwezinhle. Lolu hlobo lwesicathami luhlanganisa imisebe yokwenza lokuqala kakhulu lapho kusetshenziswa izinhca eziyinkimbinkimbi zokwenza uhlobo olufanayo olulayishwe kusayizi lwalo. I-tekniki yokulayisha ihlathiwe ukuthuthukisa ukubonakala futhi nokuconywa okulungileyo, kanye nokuthuthukiswa kwezinhca zokulula futhi kungcono ukulungiswa. Ikhompiyensa yesithawu sika chromium, nikeli, nezinye i-alloying elements ezifanisa nokwehla kakhulu kwe-corrosion resistance futhi nokuphakama kwezinhle. Likhona kakhulu ezintathu eziyi 304 ne-316, i-brushed stainless steel sheets zinikeza ukufakwa kahle futhi ukulayishwa okulungileyo, lokhu kuyindlela engcono yezinyathelo eziningi. Iziphawu zalo zinikeza ukuthi kuyindlela engcono kuzindlela ezidinga ukulula kwezokudla, ngokuthi isayizi engeye iporasi yenza ukuthi amabhakthieri asipho futhi kungcono ukulungisa. Kuzo zindlela zokudizayina, lezi sheets zinikeza iziphakamiso eziphakeme kakhulu futhi zilinde isimo samathathu ngenkathi kungcono ukulungiswa. Imisebenzi yokwenza iyenza uhlobo olufanayo lokuqala futhi isayizi esifanayo, lokhu kuyenza into engcono kakhulu yezindlela eziningi kwezinhle zokudla ezibalweni ukuya kuzo zindlela zokudizayina.