isikhwili esikhulu seshisane

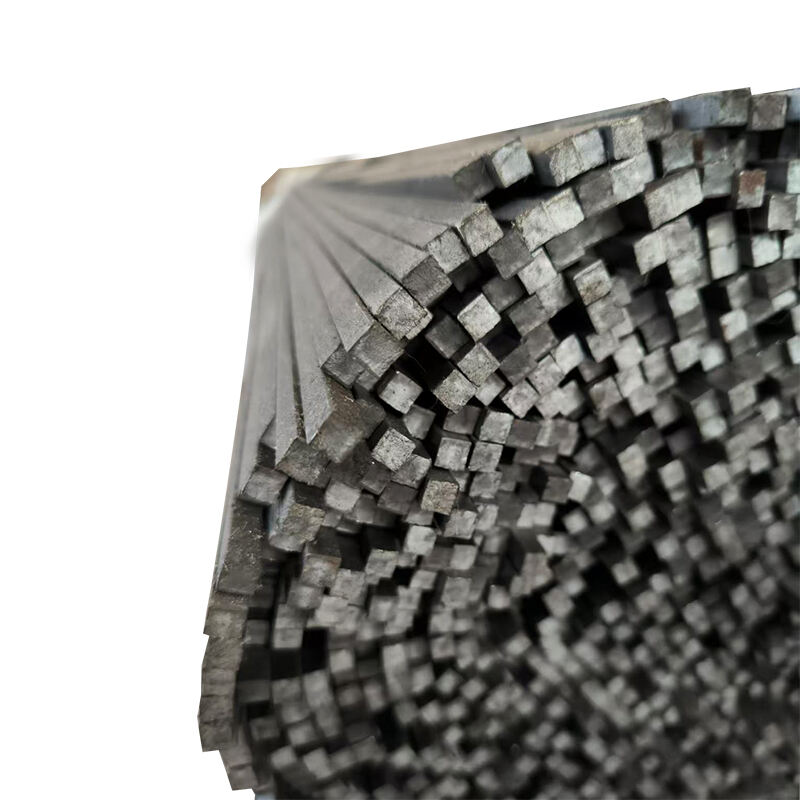

Izinkomba zomqombe wezokuhlolwa zilungiselelwa njengokwezifano ezenzakalelayo kumasebenzi oluphambene, zinezigaba elingenhla elinehlobo lelitshe kanye nekona elingenhla kuzo lonke ubude bazo. Lezi zinto ezifanayo zwenziwa ngemisebenzi emikhulu eyenza ukuthi zibe nezindebe eziphelele kanye nezindlela eziphelele. Zidla ngemikhombiso yezokuhlolwa ephezulu, lezi zinkomba zinikeza ukukhathazeka okukhulu kuma-corrosion, amandla aphakeme kanye nezixhobo zokushisa. Imisebenzi yokwenza iyiyoqo ukulawula ukuthi kuthathwe amagrade nezindlela zokushisa ukuze kutholwe amandla angcono. Lezi zinkomba ziyatholakala ezindlela ezahlukene, kanye nezokuhlolwa ezokuhlolwa, ezokuhlolwa ezokuhlolwa, kanye nezokuhlolwa ezokuhlolwa, okwenzelwe ukuthola amathiphu kanye nezinto ezahlukene. Izigaba esikhohlweni sigcina ubunzima bawo bese kutholakala ukuthi kungcono kumasebenzi apho kudingekayo ukuncipha ubunzima. Isebenziswa kakhulu kumasekteli amaningi njengezokuhlolwa, ukusebenza kwamakhimawo, ukudweba kanye nokusebenza kwamakhimawo. Izigaba esikhohlweni kungenzeka ukuthi kutholwe amadoda, ukushisa, kanye nezinye izinto. Imisebenzi yokuhlinzela kakhulu iyenza ukuthi kuthathwe izindebe, ukucopheleka kanye nezinye izinto, ukuxhomekeka kakhulu kwezinkinga ezinhlobo zasemkhakheni.